During the early 1850’s the designation used for the revolvers in service was the 100-bore, or .36 cal. Colt percussion revolver, as used by the then Republic of Texas navy. The designation remained popular in the post-Civil War era with the Model 1851 Colt Navy Revolvers. The Colt M1892 was the “upgrade” to double action and standardisation in the .38 Long Colt, which was introduced by Colt in 1875. It was first used during the Spanish-American War and the performance was not what was expected. During the Philippine War, there were further complaints where it was found the Long Colt lacked penetration of the shields carried by the insurgents. Smith & Wesson was at that stage working on an improvement of their revolvers and with the introduction of the 38 Special cartridge in 1898 that was developed by the U.S Military they introduced their K-Frame (or medium frame) revolver. The new cartridge proved to be hugely popular, but it was officially used for only a short period before being phased out by the introduction of the semi auto pistol developed by Colt and John Browning.

Although it was phased out by the military the 38 special gained huge popularity amongst US Law Enforcement and was adopted by most police departments. It also attracted a large commercial following and the 38 Special is still today one of the most popular handguns available. please also have a look at the SOUTH AFRICAN VARIATIONS which are listed separately. (Erlmeier, Brandt Ref. 368)

2022-10-07 new uploads done

The 3-D headstamp was by3-D Company Inc., (later 3-D Investments Inc and 3-D Ammunition and Bullets), Doniphan, NE. These were on cases by Starline. Code 26 was by Svenska Metallverken AB, Västerås with the 0 being for export. Code 27 was by Norma with the 0 being for export. The 38 81 headstamp was by 205th Arsenal (Previously the 60th Arsenal until the 1970s) Kaoshung, Taiwan. The specimen with the Arabic text at the top was by AWA Allendorf, Schonebeck Germany and was a contract loading for Turkey. The second last specimen with Ni-clad bullet was in all probability for Selve Kronbiegel Dornheim A.-G., Sommerda, Germany. This headstamp occurs on cartridges found in a box made by The International Cartridge Company in Germany for J. L. Galef Importers, 75 Chambers St., New York, NY USA. Reportedly the “International Cartridge Company” is a name used by Galef for their ammunition.

Aguila was by Industrias Tecnos S.A. de C.V., Morelos, México. Amron was by AMRON, Gulf + Western Systems, Waukesha, WI and dates from around the late 1960’s. ACP and AP headstamps were by Arms Corporation of the Philippines, (formerly Squires Bingham Co.). The AP headstamp with blue plastic tip was loaded with Strike Three multi-ball loads produced by Code 4 Industries Inc., Mesa AZ. These loads have three lead balls in a blue plastic sabot. Amtech was by Amtech International Inc., Cour d’Alene, ID and dates from around 1992 – 1993 on cases with plastic bodies and aluminium bases.

The BM Q headstamp was produced by Hirtenberger in Austria. The cartridge was loaded by NGA in South Africa with the Eliminator bullet, but the cases were not produced for them. Josef Mötz indicated that these cases were made for Qatar. Buffalo Rock was by Buffalo Rock Shooters Supply, Ottawa, WI on cases by Starline. Cavim was by C. A. Venezolana de Industrias Militares, Caracas, Venezuela

CCI was by Omark Industries, CCI-SPEER/Sporting Equipment Division, Lewiston ID. The CCI EX · 38 was on experimental nickel-plated steel cases made in the early 1980’s. The brass cased CCI 38-Special was reportedly by CCI in Mexico for Peru. The C.I. headstamp was by Cascade Cartridges Internacional, Mexico and was an early headstamp dating from the late 70’s to early 80’s.

CPM was by Canadian Professional Munitions Ltd., Alberta Canada on cases by Olin for CPM in 1990 for the US Air Force. Dela was by Dela Enterprises Inc., Escondido, CA. Cases were made by SAKO for Dela for signal cartridges. Cases were later sold to REMCO Co. from Utica, NY and were loaded as shot cartridges. Denver is by Denver Bullets & Ammunition Inc. Denver Co. with cases by Starline. DGSN was for Direction Generale de Securite Nationale, Morocco, cases by Gevelot. ELD is by Eldorado Cartridge Co., Boulder City, Nevada and loaded with the Starfire bullet

FAME was by Fábrica de Municiones del Ejército, Lima, Peru. The F C 57 headstamp was a military contract loading. By the end of WW2, there were a variety of 38 cal. revolvers in service and many were using the 158gr. FMJ bullet that was developed by Remington. There were complaints however that the loading gave to much recoil and excessive muzzle-flash, especially in shorter-barrelled weapons. Remington did however develop a lighter 130gr. copper alloy bullet in 1948 for potential military and police loads. With the outbreak of the Korean War, additional orders were necessary to meet requirements and both Remington and Winchester were contracted to provide stocks. In August 1953 the Ordnance Department made the 158gr. FMJ bullet obsolete for Army use and adopted the 130gr. as the M41 for the Cal. 38 Special Ball Cartridge. (See also HWS.3 p. 3-4). The L E on the headstamp is for Law Enforcement.

F.C,L was by CCI (Cascade Cartridge International) Mexico for F.C Lovelock, Adelaide, AUS, probably in the mid-1960’s.

F.M. was by Fábrica Nacional de Municiones, Santa Fe, México. FM FLB is by Fabrica Fabrica Militar Fray Luis Beltran. On April 21, 1961, the old F.M ‘S.L’ (San Lorenzo Military Factory) changed its name to what is known today as Fabrica Fabrica Militar Fray Luis Beltran. Together with military ammunition, it also manufactures ammunition for the civilian market. The FNM headstamp was by Fábrica Nacional de Municiones, (previously Fábrica Nacional de Cartuchos) Santa Fe, México. It is unknown who made the Fowler headstamp, but all cases were aluminium were sometimes loaded with a red wax bullet. Fremel was by Manufacturing & Supply Co. London, Ont., Canada and was a combination of the names of the owners Fred and Melodi Pollack. The company was in operation from 1980 – 1985 and cases were made by Starline.

The Geco headstamp was by Gustav Genschow & Company, Durlach, Germany

These Fiocchi loads were special case blanks made for an underwater speargun.

The intertwined <GG> was by Gévelot S. A., France. G&S headstamp is by G&S Munitions (Greg & Sue Yoha). Hereford, AZ. Glaser was by Glaser Safety Slug Inc., and was introduced in 1981 on cases by Starline. This was one of the original loads that contained the shot in a matrix of liquid teflon. Gromack was by Gromak Industries, Santa Maria, Ca and was early Starline manufactured dating from around 1976. H&R is by H & R Armory (Horner Munitions) San Diego, CA with cases by Starline during 1981-1985. Harrington headstamp was by Harrington Ammunition Inc., De Witt, MI also with cases by Starline from around 1978 to mid-1980’s. Hi-Per was by Hi-Performance Cartridge Corp., Greensboro, NC that later became High-Performance Ammunition, Apollo, PA. This specimen on cases made by Olin.

HP headstamp with date in all probability for Police contract ammunition. The last specimen was also loaded with the NGA Eliminator bullet.

Last specimen from IMI was used for loads for the French Police with the flat tip FMJ bullet

INDUMIL is for Industria Militar, Soacha-Almacen Armas y Municiones Bogota, Colombia. The IVI 68 headstamp occurs on military contract ammunition loaded with a 150 gr RN FMJ bullet and have only been encountered with the 1967 and 1968 dates. The “FX” on the IVI headstamp identifies these as special training cartridges loaded in a shortened brass case and firing a clear-plastic bullet filled with a die marking compound. Both pink and blue marking loads are known. The notes I have for the IWK Blank was that it was a contract for the Swedish Airforce for dog training. KTW was established in the late-1960s by Dr. P. J. Kopsch, Dan Turcus Jr. and Donald F. Ward who developed and produced a special Teflon coated penetrating bullet initially made from an alloy called Kennertium.

LAPD was for the Los Angeles Police Pistol and Revolver Association on cases made by Starline.

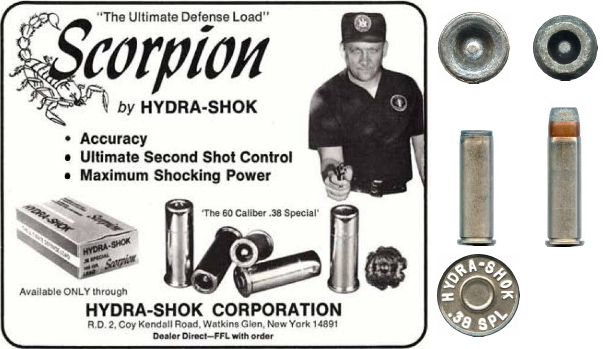

The two inside primed specimens were by Leon Beaux & Co, Milan Italy and from around the 1920’s.The L C 7 9 headstamp is loaded with the NGA Eliminator bullet. The specimen with L C 8 0 headstamp is the Cartridge, Cal. .38 Special, Ball PGU12/B that is discussed below on cases made by W-W SUPER. LE was by Leader Trading GmbH, Germany with cases made for them by Fiocchi. LIBERTY was by Liberty Cartridge Company Marietta, GA.The nickel cased LIBERTY specimen on the right is the Scorpion Hydra-Shok load. The LIBRA shot load is from the Czech Republic and used an S&B case that was overstamped

LRS was by Lead Recovery Systems Inc. (a division of 3-D Co.) from Doniphan, NE from around 1975 – 1977. MEN is by Metallwerk Elisenhütte G.m.b.H. Nassau, Lahn, Germany. The two dated MEN versions are Quick Defence (QD 1) versions designed by Hans Shirnecker and was a competitor to the Action Geschoss round developed by Dynamit Nobel during the late 1970’s for anti-terrorist cartridges. The MESKO specimens are SHORT STOP variations first manufactured by MESKO in 1986. Metallverken is by AB Svenska Metallverken Västerås, Sweden. MF is for Military Small Arms Factory No.1, Footscray, Australia. The small ‘c’ on the second specimen is for cases produced for the commercial market.

MIDWAY was by Midway Arms Co. Inc., Columbia, MO, with case made by Starline. MMI was a triplex load by Multiple Munitions Industries Inc. Gretna, LA. MRP was done by CBC Brazil for Magtech Recreational Products, Las Vegas, NV. NATIONAL was National Cartridge Co., a division of Firearms Management Inc. Atlanta, GA. Cases were in all probability done by Starline. NEVINS was done by Olin for Nevins Ammunition Inc., Boise ID from 1980 up to around 1989 although some were also done by Starline.

Norma variations

Norma variations

ORBEA is Cartucheria Orbea Argentina S.A., Buenos Aires Argentina. Otto Witt was a commemorative headstamp done by Bertrams Australia. Otto was one of the biggest collectors of 38 Special.

PAC is by Polytech Ammunition Co., Minden, LA. The PALCHER headstamp is by TECHSTAR ENGINEERING INC. Santa Ana, CA. See also IAA Journal 392 p. 43

P-R is by Productos Regiomantanos, Monterrey, Mexico. PRECISION is by Precision Delta Corp. Ruleville, MS. RANGE headstamp is by the Range Corporation, OH

Last specimen loaded with the NGA Eliminator bullet.

Last specimen loaded with the NGA Eliminator bullet.

With the adoption of commercial S&W and Colt revolvers in 38 Special in the latter part of 1942 the standard lead commercial bullets could not be used because of the restrictions placed by the Hague Convention. Remington was contracted early in 1943 to develop jacketed bullets and because of a copper shortage Remington manufactured copper clad steel jacketed bullets with lead core. These cartridges were also produced during the Korean War. These cartridges had the hyphen taken off from the headstamp.

During early 1943 the US Navy requested the development of a tracer round from the US army Ordnance Department for use in the Cal. .38 revolver to be used by air crews for signal purposes in emergency situations. Bullets were red tipped with an average trace length of about 350 yds.

During the early 1960’s the Navy and Marine Corps did joint tests on a series of pyrotechnic devices for signal purposes. These tests were done at Patuxent River NAS and at the USMC Development Centre, Quantico. Cases had a wide circular crimp on the case mouth and bullets with red tip with specimens with R A 6 6 headstamp.

The notes I have on the R A 5 6 headstamped specimen was that it was an experimental frangible bullet loaded during the 1950’s.

The first specimen is part of the first Air Force contract from 1959 – 1960 for practice ammunition for survival training. This specimen is loaded with a red wax bullet. See also HWS 3 p.15

The first specimen with red primer annulus and magenta tip is described in HWS 3 p.11 as a red signal cartridge with designation EX 130 MOD 0 dating from January 1968. It was specifically designed for use by downed pilots during search and rescue operations. The bullet was of turned brass loaded with sufficient velocity to pierce a normal jungle canopy with a red trace that burned for 5,5 to 7,5 seconds up to a height of 1,700 feet.

This specimen is part of the third contract dating from 1961 when the Air Force ordered a quantity of training ammunition for survival training courses. This contract was by Speer and used a mixed lot of headstamps loaded with white polyethylene bullets flush with the case mouth. See also HWS 3 p.16

First specimen is loaded with the 90gr. HEMI bullet. The 4 dots mean it was loaded on cases by IVI Canada. The dots on the second and third specimen loaded with NYCLAD Bullets are on cases supplied by OLIN. S&W-F is for Smith & Wesson Fiocchi on cases also by OLIN dating from 1973.

Last specimen was loaded by Dela Enterprises for red smoke and red flare signal loads. The flare loads are identified by the small teat on the tip of the bullet.

Southern Ammunition Company, Latta SC. Loaded by American Ballistics with a 33gr. HYPERSONIC XAL+P (Expanding Aluminium) bullet

Santa Barbara SPAIN

Santa Barbara SPAIN

Squires Bingham Corp. (Later Arms Corporation of the Philippines). Fist two specimens were marketed under the Concorde and Sterling brand names during the 1970 – 1980’s. Last specimen dates from the 1990’s.

SDM – Shooters Den Munitions, Rush Center, KS. Cases were manufactured for them by Starline in the early 1980’s. SME – SYARIKAT MALAYSIA EXPLOSIVES LTD, Malaysia. SOS – Manufactured by Patronenfabrik Lichtenworth-Schlesweg Fabrikation, (formerly Georg Roth) Lichtenworth, Austria in the 1920 – 1930’s for the US Market. The meaning of SOS is unknown.

Selve Kronbiegel Dornheim , SOMMERDA

Selve Kronbiegel Dornheim , SOMMERDA

The first specimen is an MBA Short Stop round as described in Mel Carpenter’s excellent book: An Introduction to MBA Gyrojets and Other Ordnance. The Stun Bag concept was developed by Robert Mawhinney who adopted the concept in small 1-inch bags filled with 55 grains of No. 12 lead shot. Although the range was about 200 feet, it was harmless at the distance, but it was lethal at distances under 50 feet. The idea was to deliver all the energy inside the target with no ricochet, making it less lethal to bystanders. Tests were done by MBA, Speer as well as the US Air Force and they adopted it as standard issue for aircrews of the Military Aircraft Command. (See also: An Introduction to MBA Gyrojets and Other Ordnance p. 289 – 296)

Sectioned Short Stop round. Source: Internet

Sectioned Short Stop round. Source: Internet

Frangible Loads on Starline cases

Frangible Loads on Starline cases

STAR – Star Reloading Co., Indianapolis.

Cartridge, Delay, 0.3 sec (yellow) for the Delay Initiator of the F-4 aircraft escape system. Made by Ordnance Engineering Associates, Inc. (OEA), Des Plaines, Illinois.

Metal Piercing

Metal Piercing

Thai Arms Bangkok, Thailand by Squires Bingham, Philippines

Thai Arms Bangkok, Thailand by Squires Bingham, Philippines

USAC (United States Ammunition Company) – They were first made in 1982 in Seattle, Washington but then they moved to Tacoma, Washington. The company went out of business in 1991.

The VIC GOVT headstamp is for the Victoria State Fish and Game Department. The VIC-POLICE headstamp is for the Victoria State Police. Cases by Bertrams

This headstamp occurs on cases produced by Starline in the early 1970s for WAHIB Arms, which was owned by Robert W. Hibbard. The company was named for the owner’s father and son, both named Warren A. Hibbard.

This headstamp occurs on cases produced by Starline in the early 1970s for WAHIB Arms, which was owned by Robert W. Hibbard. The company was named for the owner’s father and son, both named Warren A. Hibbard.

Training round by Walmax Inc., Glendale, CA

Training round by Walmax Inc., Glendale, CA

During the latter part of 1966 requests were received from Vietnam for a combat load that would increase the effectiveness of the 38 Special after complaints that the M41 Ball load lacked effectiveness and accuracy by aircrews for jungle survival or for special operations missions in clearing Viet Cong tunnel complexes. AAI Corporation was contracted via Frankford Arsenal for the development and in March 1967 the shot load developed by them was designated Cartridge, Ball. .38 Special, Lead Shot XM667. It utilised a glass-reinforced nylon sabot containing 14 No.2 lead shot pellets.

In order to improve the lethality of the 38 Special at close and medium ranges the Air Force requested Frankford Arsenal in 1960 to investigate the feasibility of heavier FMJ bullets and it was designated Cartridge, Cal. .38 Special Ball XM142. The 158gr. bullet from WW2 was used but with a copper alloy jacket. Contracts were leased to Remington and Western Cartridge Company but it was found that there were a lot of bullet-in barrel malfunctions and the project was suspended pending investigation and residual stocks were destroyed. (HWS3p. 4)

In late 1971 Frankford Arsenal started design work to reduce the bullet-in-bore malfunctions. The first version used a GM semi wadcutter bullet that was seated deeper in the case but these were found to produce velocity and pressure deviation problems, so the case length was shortened by 1/10th of an inch to solve the problem and second lot was loaded by WCC in 1972 and was designated: Cartridge, Cal. .38 Special, Ball, M41E1.

The W C C 8 1 specimen was loaded with the NGA Eliminator bullet.

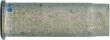

This is a Thunderzap round that was invented by Bruce McArthur, from Clarkston, MI and was marketed by Richard Davis of Second Chance Body Armor. Bruce McArthur did tests with various calibers, but the only ones that were ever marketed were 38 Special and 45 ACP and was made of a light weight thermo moulded teflon with a huge hollow cup. It was designed as a safe round for home defence yet still have sufficient stopping power. The light-weight bullet achieved a velocity of around 2,800 fps from a four-inch barrel which made it devastating at short range but relatively ineffective beyond around 100 yards. Ultimately this round was not successful for one reason: political, as the round will do enormous damage but because it disintegrates it leaves no ballistic trace. There was also a good article HERE

Frankford Arsenal met with Air Force personnel during September 1973 to discuss the replacement of the M41 cartridge. The Air Force requested a round with a higher velocity in the range between 1,125 to 1,150fps in order to improve effectiveness and lethality. Original tests with the M41E1 bullet showed serious accuracy issues and it was thought that it was caused by the sharp shoulder of the bullet and a redesign with a more rounded shoulder tested with improved the accuracy issues and this bullet was designated the M41E2. It was decided to continue tests with the M41E2 bullet, but initial tests were unsuccessful as a result of pressure problems and velocity deviation, failing to reach the velocity requirements set by the Air Force. This was a result of the shortened case and in November 1973 development was done with a standard length case in order to meet Air Force requirements. Continued tests with different propellants were done and in March 1974 the standard length case with a deep seated M41 bullet was presented for acceptance at the Cartridge, Cal. .38 Special, Ball PGU12/B. Production of the PGU12/B was done primarily via commercial contracts.

38 Special +P Ultra Shock made by Ultra Shock Defensive Ammunition Co. CA

38 Special +P Ultra Shock made by Ultra Shock Defensive Ammunition Co. CA

Delay Cartridges. 1st Specimen ‘CTG. DELAY MK 36 MOD O LOT 6-SR-0577’ 2nd Specimen ‘CTG. DELAY MK -6 MOD -1 LOT 6-IHM-0269’

Shown at 200% scale

Shown at 200% scale

Cartridge, Delay, 0.4 sec. (red) for the Delay Initiator of the F-4 aircraft escape system. Made by Ordnance Engineering Associates, Inc. (OEA), Des Plaines, Illinois.

Zero Ammunition Co., Cullman, AL., USA. – Cases with small font made by Olin Corporation after 1985

Zero Ammunition Co., Cullman, AL., USA. – Cases with small font made by Olin Corporation after 1985

The aluminium cased paintball training cartridge was by SNC Industrial Technologies Inc., Valcartier Canada. The grey training cartridge with SLS headstamp was by Sportovni a Lovecke Strelivo s.r.o. Parbdubice, Czech Republic and dates from the early 1990’s. The light blue short-range is by DAG, Germany. It has the DAG and 38 SPL on the case. The darker blue training cartridge might be from the Czech Republic, similar to the SLS version. The blackened case with translucent plastic bullet was by Plastic Training Products Co., Bloomfield, NJ. It only achieved limited production and was marketed under the name “Dunn’s Re-usable Training Ammunition”. The orange plastic dummy was by Precision Gun Specialties Inc., Sheridan, MI.

The yellow plastic training cartridge was by KERRCO. Inc. Hastings and Lincoln, NE. it was loaded with a black plastic finned projectile and dates from the late 1970’s to early 1980’s. cases were stamped with a number on the base, this one being a 10. The cream-coloured case might have been by Nova Plastics, Orange, CA but not confirmed. See also Otto Witt’s excellent work on the 38 Special, Vol.2 p.378. The plastic snap-cap was probably by The Four Company (TFC), Villa Carcina, Italy and dates from around 2001. See also Otto Witt, Vol. 2 p.375.