The history of the 7.62 NATO RIFLE have been documented in South Africa in relative detail up to now. Not everything is known yet because the South African government has as yet not been prepared to give any access to the Armscor Archives. (There used to be a link to the SAAACA website regarding research into the RSA history and development of the rifles, but that link seems to have disappeared from their website). Until such time, we have to use whatever other available resources in order to provide the collecting community with as much information as possible.

Much more research has been done by various collectors in South Africa over the years concerning the history and development of the 7.62 x 51 NATO rifle in South Africa as opposed to the history and development of the cartridge itself. Because of limitations in technology during those early years, much detail has been lost or was not reproduced at an acceptable quality. Researchers for the most part had to rely on faxed copies and copies of copies as well as hand-drawn headstamps and pictures of cartridges. This work will try for the first time to bring together all the sources and present it to collectors in a high quality version. Although every effort is being made to make this as complete as possible, there are still variations that are not documented and every now and again, something pops up. The benefit of having this electronic version is that it can be quickly updated with any new discovery.

One problem with conducting research of this kind is that much of the records were lost during the early 1990’s. Many, or let’s call it most of the people working at these facilities were replaced as a result of affirmative action during the latter part of the 1990’s and as a result of that, most of the information was also lost. There are lots of developments currently at Denel, but the majority of these are foreign contracts. With Denel being classified as a “key point” in terms of security, almost all these new developments are not and maybe will never be available to us collectors in South Africa. Ironically I have on more than one occasion encountered RSA manufactured cartridges at international cartridge shows that we as South African collectors did not even know about.

Please use the contact form on the welcome page to send comments, ideas, data and pics or any form of research that can add to this.

HISTORY

South Africa started manufacture of the 7.62 NATO in 1961. South Africa became a republic on the 31st of May 1961 and started to phase out the 303 British in favour of the NATO round as a result of us no longer being members of the Commonwealth. The first cartridges were manufactured at the Ammunition Branch of the SA MINT, hence the headstamp “SAM”. I am still looking for more info on the pre-1961 period where South Africa made use of imported components.

• The pre 1961 period

• South African Mint 1961 – 1965

• PMP 1965 – 1972

• A Series 1973 – 1983

• Sterile and semi-sterile series (mid 1970’s – early 80’s)

• LA and WA Series (1977 – 1982)

• B Series (1981 – 1982)

• A Series (NATO Standard) contract load (1974 – 1975)

• NEW Series (Post 1983)

• PMP Commercial

• Other Commercial

THE PRE 1961 PERIOD

Although not the focus of this project, it would not be complete without some reference to the adoption of the FN Rifle in South Africa. Some of the research about the FN Rifle comes from the South African Arms and Ammunition Collectors Association website.

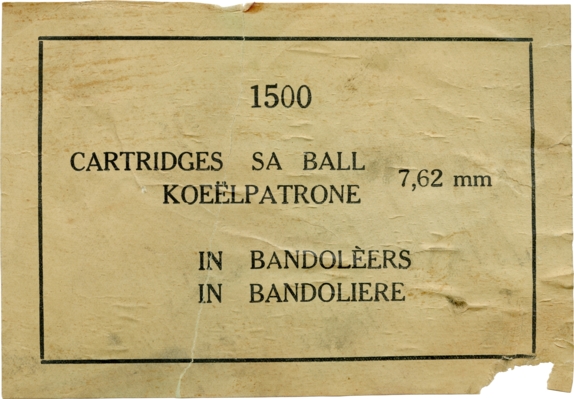

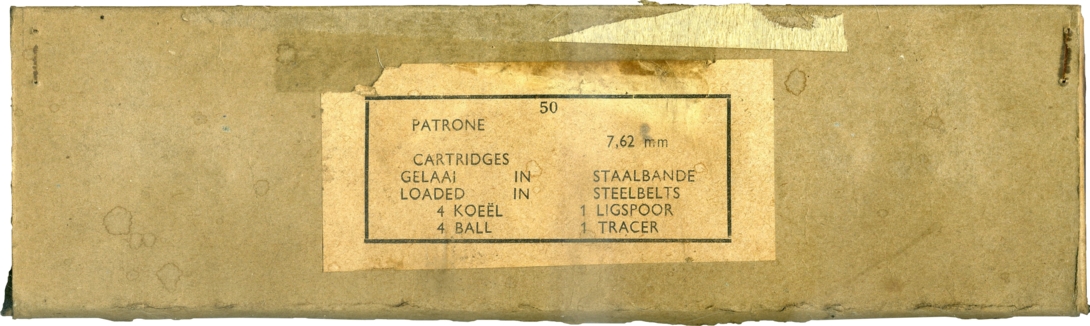

Possibly as early as the very late 1950s negotiations were started with Fabrique Nationale (FN) of Liege, Belgium to produce a quantity of these FAL rifles for the South African Defence Force. This will also be true about the ammunition used as can be seen below on the currently available box and crate labels. It is assumed at this stage that all ammunition prior to local production was imported and not assembled locally. These labels however were printed in English and Afrikaans, which is similar to Dutch.

The first batch (or batches) of rifles arrived in the SA in 1960 or 1961 and were of the early M1/M2 type (no flash-hider and standard gas plug). Later deliveries, presumably as a result of ‘lessons learnt’, were of the FAL type with 22mm grenade launcher flash-hider and gas plug, some being a unique variation of the folding stock ‘Para’ model as well as the FN-FALO or ‘Heavy Barrel FN’. All the FN made contract rifles procured for the SA Defence Force were identified, as was common practice at the time, with the purchasing nation’s coat-of-arms roll-stamped onto the right hand side of the magazine well. Additional smaller quantities of non-contract models were purchased by, and for, the SA Police and the SA Prisons Service.

At some time in the early 1960s an agreement was signed between FN and Armscor whereby the FAL would be produced, under licence, by LIW (Lyttleton Ingeneurswerke/Lyttleton Engineering Works), an Armscor/Denel subsidiary located outside Pretoria. The SA produced version was officially named the ‘R1’ and the first rifle produced, serial numbered 200001, was presented to the then Prime Minister, Dr Hendrik Verwoerd, by Armscor and is now on view at the National Museum of Military History in Johannesburg. This rifle is non-typical of regular R1 production as it boasts a wooden stock and leather sling and there is some evidence that it was not assembled from 100% SA manufactured components. This might also be the case with the ammunition components. As far as could be ascertained, the SADF never produced the domed brass primers as can be seen on early SAM 7.62mm ammunition. This might mean that during the late 1950’s and early 1960’s, Armscor imported components from Belgium and ammunition was assembled locally at the SA Mint. It is also noted on early SAM loaded ammunition that a ringed primer crimp was used on 1961 and 1962 production, but from 1963 onwards, the standard 3 stab crimp. The ringed primer crimp was however standard on 303 British ammunition that was loaded at the Mint at that stage.

On the box label below it shows the FN 57 ⊕ headstamp.

Image courtesy Arno Klee

Image courtesy Arno Klee

FN 57 ⊕ Box. Courtesy Will Reuter collection

FN 57 ⊕ Box. Courtesy Will Reuter collection

SOUTH AFRICAN MINT

From date of first production, which would be after May into the latter half of 1961, until 1963 all rounds were loaded with a convex (domed) brass primer. There was however a period in 1963 where a flat brass primer was used. In 1964 there was a lot that was again manufactured with a domed brass primer, but it is not known for what reason or how may lots and it might have been the last of the imported components from FN. For the rest of 1964 and into 1965 toward the changeover to PMP only the flat brass primer was used. Two different primer crimps were used. A 3 stab primer crimp was used from start until 1965, except for a period in 1962 -1963 where a ring crimp was used. Case mouth seals were black, purple, green or clear and it is not thought to resemble anything specific. Only the 1961 manufacture has a case mouth crimp and again only the earliest production because there is a 1961 version without the mouth crimp. All variations have a Gilding Metal (GM) bullet. No GMCS version has been reported.

Variations known from this period include BALL, DRILL, AP, WARMER PROOF, HIGH PRESSURE TEST, SHORT RANGE EXPERIMENTAL and GRENADE BLANK DUMMY.

First specimen is a BALL round with the segmented case mouth crimp

First specimen is a BALL round with the segmented case mouth crimp

The 2 variations found on early SAM production

The 2 variations found on early SAM production

SAM62 version with belt link

SAM62 version with belt link

Shown are the different case mouth seals used, namely black, light green, clear and purple. the fourth specimen is a “barrel warmer”. The remnants of the purple tip can still be seen. Normal GM bullet, it was used to warm barrels before testing.

The first two specimens again shows the different primer crimps used. Also seen for the first time on 1963 production is the flat brass primer, as well as the Pressure Test load. As can be seen below, the early Pressure Test loads used a green tip.

The first specimen is without any case mouth seal. Interesting to note the 2 NICKEL DRILL versions with the first one having no case flutes.

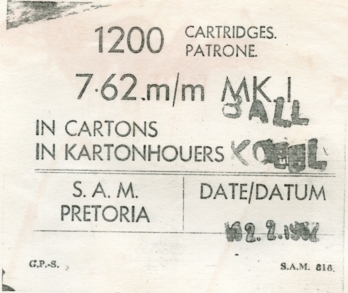

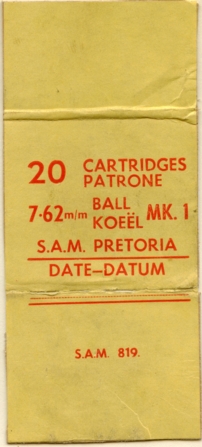

(Box images courtesy Will Reuter collection)

(Box images courtesy Will Reuter collection)

This is the last version by the SA Mint. Changeover occured here to PMP production. The box label is from this SAM 65 round, although there is unfortunately no lot number. Not also the spacing on the headstamp. It was only for the 1965 case.

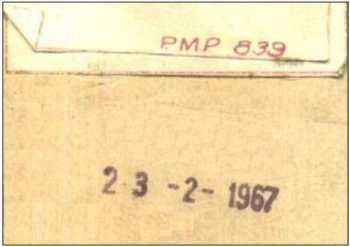

PMP

Pretoria Metal Pressings was placed under the control of the Armaments Board in December 1964 and the designation changed to Pretoria West Metal Pressings. Although the change happened in 1964, the first headstamps only started in 1965. The factory operated in that format until 1972. With the change from SA MINT to PMP there was an overlap in the headstamp during 1965. It was not the case however with PMP. The Armaments Development and Production Corporation (ARMSCOR) was founded in 1968 and the PMP factory was placed under ARMSCOR control and redesignated Pretoria Metal Pressings (Pty) Ltd. It is during this time that the headstamp changed from MK.1 to A1. There is no changeover headstamp for that period. A lot of developments were done during this period with the addition of many variations.

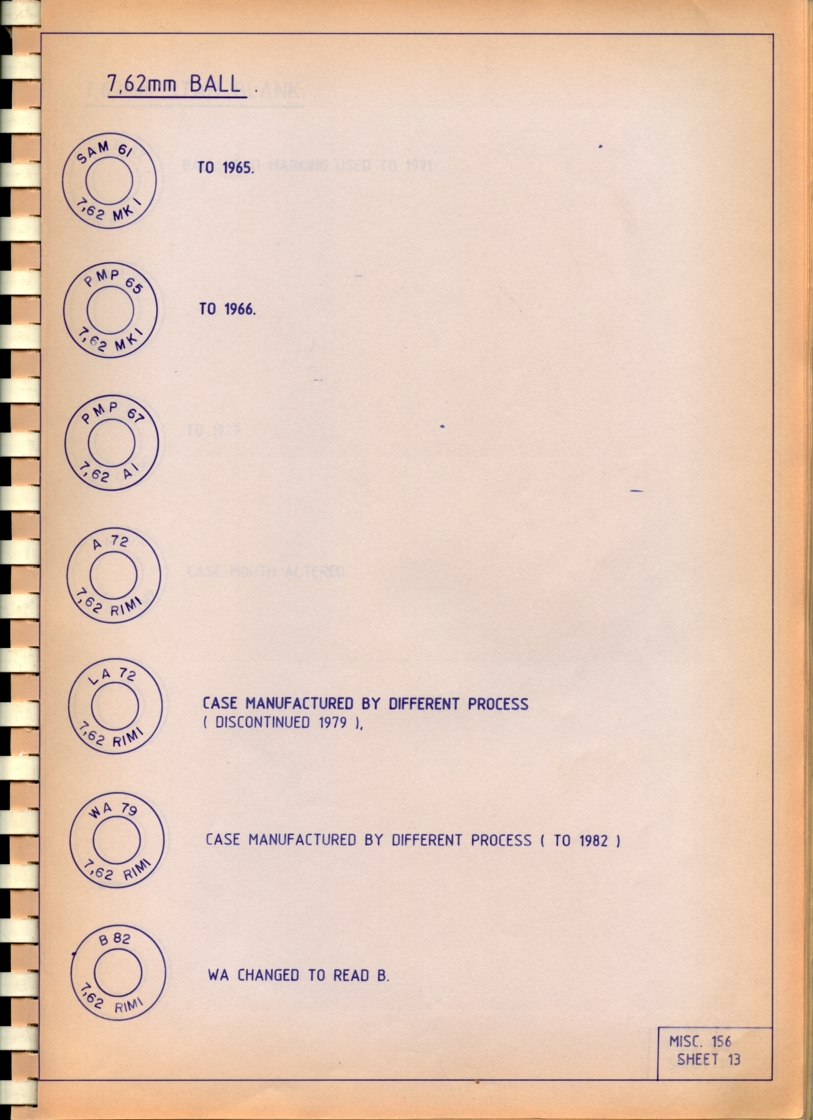

BALL (1965 – 1972)

All specimens have brass cases with GM bullet, purple PA and no case mouth seal.

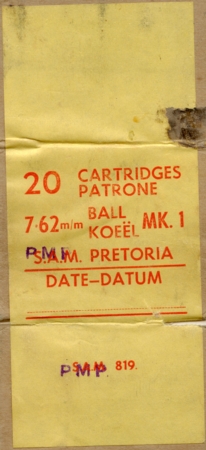

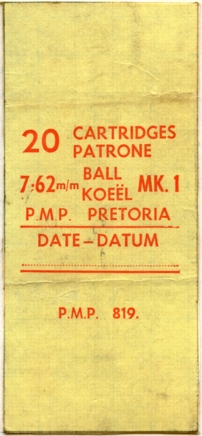

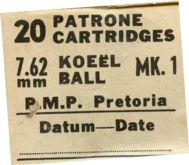

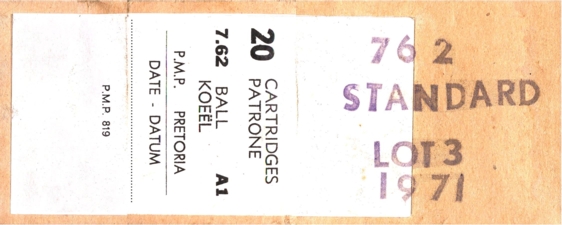

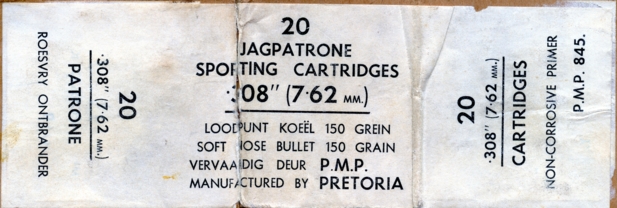

The 1st box had the headstamp PMP 65. It shows the change-over from SAM to PMP where the box label has been overstamped P.M.P. The second and third boxes had the headstamp PMP 66 and 67. The middle one shows the old yellow box, but the printing was done as PMP. The last box shows the change of colour to white/cream which is standard for all 7.62 NATO boxes since.

Double strike on headstamp

Double strike on headstamp

Interesting to note is that on the PMP 66 version the mark is stated as MK.1 and on the PMP67 version as MK 1.

The changeover from MK.1 to A1 occured in 1968. there is no change-over headstamp from 1967 to 1968. There is a variation reported but not confirmed of a 1968 case with a chromed bullet. The PMP69 version, as with the PMP69 9mm ball are rather scarce and it has been suggested that the entire year’s production was exported. There was apparently a newspaper report regarding this where a confidante of Genl. Charles de Gaulle acted as a go-between for the sale of South African manufactured cartridges. This is unconfirmed at the moment and I am looking for the article in order to ascertain if this was indeed the case.

On the 1971 and 1972 cases there were no dots in the PMP name.

On the 1971 and 1972 cases there were no dots in the PMP name.

This is a new primed empty case that was never loaded and does not have the purple PA. It is the only one and might have been some sort of reject that failed a quality test somewhere during the drawing process.

This is a new primed empty case that was never loaded and does not have the purple PA. It is the only one and might have been some sort of reject that failed a quality test somewhere during the drawing process.

There is nothing to distinguish this round as a BALLISTIC STANDARD, other than the text written on the cartridge. Round has a normal GM bullet. I also have a cartridge with the bullet being slightly magnetic. It is not a GMCS bullet as there is no mention that such a round was manufactured.

Two unknown variations, although it might be Marking Cartridges, where differents units coloured the bullets so that it would leave some residue on the target for scoring purposes. This was done on unit level and not factory level. First specimen has an OLIVE GREEN/CREAM GM bullet and the bottom variation has a thick white paint cover on GM bullet.

BLANK (1965 – 1972)

First loaded in 1967 and all specimens have brass cases. Purple PA noted from 1967 – 1969, with later 1969 version up to 1972 with a clear/honey coloured PA. Original mouth seal red on 1967 – 1969 versions, with a 1968 version with green mouth seal. From later 1969 to 1972 mouth seal was a clear/honey coloured, except for 1 specimen in 1972 with a green mouth seal.

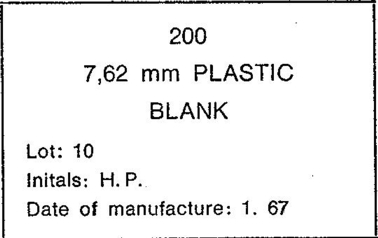

These blanks by HP are found in large quantities in South Africa and might have been used by the military

During the mid 1960’s to early 1970’s the SADF (South African Defense Force) did some experiments with plastic blank and short range ammunition. Very little is known about the project however and very few rounds survived. The cartridges utilised an aluminium insert on plastic body with a small brass primer that was secured by three stab crimps.

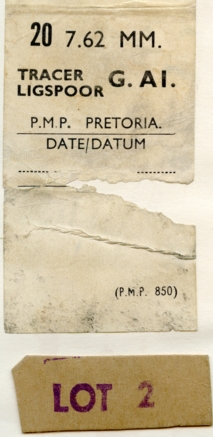

TRACER (1965 – 1972)

Original reports from PMP was that production started in 1967, but the earliest headstamp is from 1968 as no cases from 1967 have been seen. Brass case with brass primer and red PA. One batch from 1969 was made with a red case mouth seal and may have been a contract for a foreign government. From 1968 – 1969 the bullets are GMCS but changed later in 1969 to GM only. All specimens are identified by a red lacquered tip, cannelure on the bullet and a red PA. The letter G is also introduced on the headstamp.

Note on the 1968 date the dots on 7.62.G.A1, whereas there are no dots on subsequent years and also no dots on PMP after 1969.

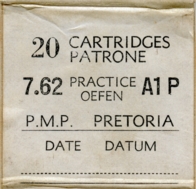

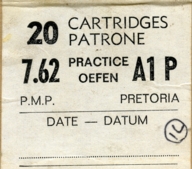

SHORT RANGE – PRACTICE 1969 – 1972

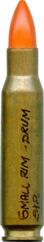

This was a rather comprehensive project by the looks of all the different variations in the blue series. The bullets that were adopted however were the orange series that resembles the French short range bullet and was also initially supplied by them. They were locally called “ROOIBEKKIE” or “little red mouth”. Although PMP stated that production started in 1969, the earliest headstamp only dates from 1970. Ordinary ball cases were used with flat brass primer and purple PA.

The following are all on the PMP 71 headstamps:

Variations of the Blue Series

Variations of the Blue Series

Very few specimens have been seen with the PMP72 headstamp because the orange version was the officially accepted version, so there would not have been any more trials with later dates.

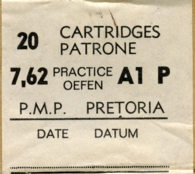

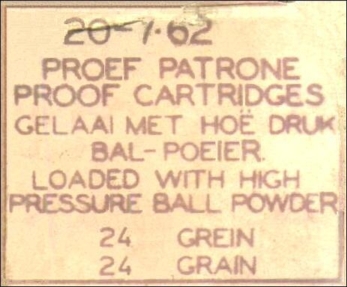

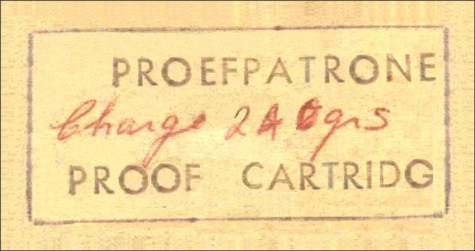

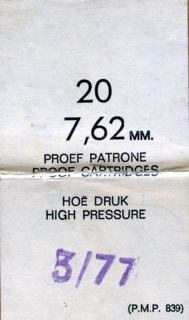

PROOF (1965 – 1972)

The earliest proof cartridges used a green tip as well as the letters HP (High Pressure). Later variations (1970 onwards) used a honey tip and PA or sometimes a honey coloured base. Warmer cartridges are identified by the purple tip and sometimes a purple base.

There is no reference to any with the P.M.P. 69 7.62 A1 headstamp

There is no reference to any with the P.M.P. 69 7.62 A1 headstamp

Again no reference to the PMP69 being made. Note that on the P.M.P. 68 headstamp there is no dot after the HP

Again no reference to the PMP69 being made. Note that on the P.M.P. 68 headstamp there is no dot after the HP

In 1970 the tip was changed from green to honey coloured

In 1970 the tip was changed from green to honey coloured

No mention is made of any with PMP71 headstamp. In 1972 the purple PA was replaced by a honey coloured PA or base.

No mention is made of any with PMP71 headstamp. In 1972 the purple PA was replaced by a honey coloured PA or base.

SUBSONIC (1972)

Reportedly for police use, only three versions have been examined thus far. The first is on a PMP66 case and a PMP 72 case with clear PA and 2 lead bullet variations.

GRENADE BLANK (1972)

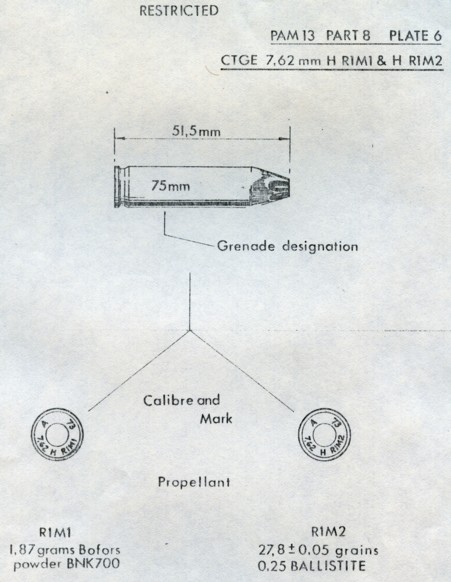

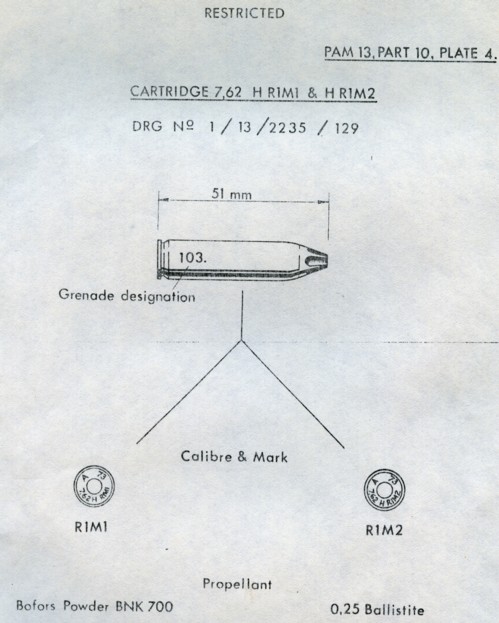

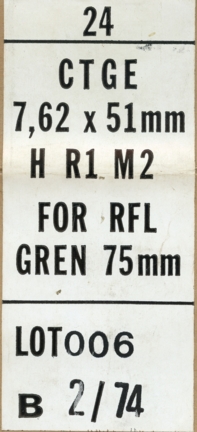

Only one example is known to have been made by PMP on a 1972 ball case with purple PA and 3 primer stab crimp. It has “75 mm” stamped in black on the side which refers to the grenade used. The printing on the grenade was as follows:

GREN. RIFLE A/TK

75 MM PRAC. ACC

A – 4 – 72

And on the tail piece: A 2/71

ACCELERATOR (1965 – 1972)

There are no records of tests being done during this period and it might be that this case was used because it was available. Testing only began during the late 1970’s. It is the only case examined from this period

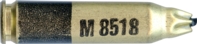

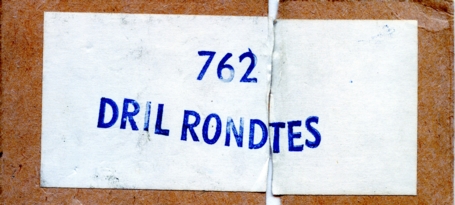

DRILL (1965 – 1972)

Relatively few versions are known from PMP. It may have been that there was still a surplus from the old SAM batch. All were normal ball cases with GM bullet and wood distance piece.

The PMP68 version has a silver type paint on the bullet, neck and shoulder. Purpose unknown but it might have been from some armoury as a type of gauge, but this is speculation only.

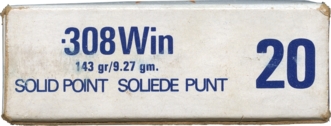

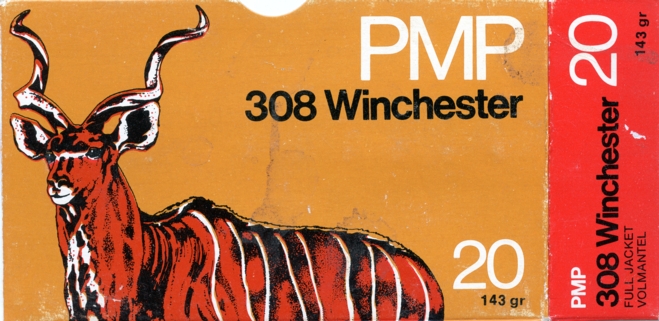

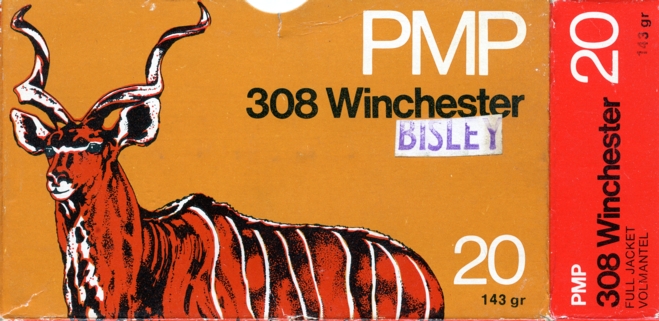

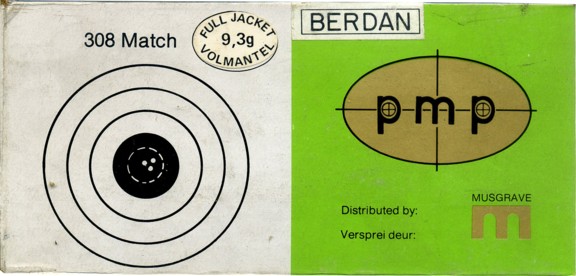

COMMERCIAL (1965 – 1972)

The earliest commercial version is known from a PMP66 case. Commercial GM softnose bullets by PMP are known in three weights, namely 150gr, 168gr and 180gr. GM and later MATCH versions were loaded in other weights (from 143gr. and up)

A SERIES (1973 – 1983)

In early 1973 the new headstamp series was launched. The PMP was replaced with an A, together with a two digit date. The A was for ARMSCOR. Also introduced was a variation of the British Modelling System (L1A1), where the R1M1 was used. R denoted South Africa (RSA) and 1 denoted the first model of the specific calibre. Any change that would affect the operational ability or efficiency would necessitate a change from R1 to R2 etc. M1 is the first mark of the specific model and any concession or deviation from manufacturing specification that was granted to a manufacturer but would not affect the operational efficiency of the design would then change the Mark from M1 to M2 etc.

BALL (1973 – 1981)

1975 was the first time that a copper primer was used

1975 was the first time that a copper primer was used

In 1977 we see the introduction of a smaller size font on the headstamp. On the original size there is also the introduction of a comma instead of a point on the caliber designation.

In 1980 there was again the use of the “larger” headstamp used up to 1977, but later changed again to the smaller font. The last specimen is the only ball case from the entire A-series without the standard 3 stab crimps on the primer.

No A82 version has been seen, only on the B-Series. The A83 version is a Bisley match load.

No A82 version has been seen, only on the B-Series. The A83 version is a Bisley match load.

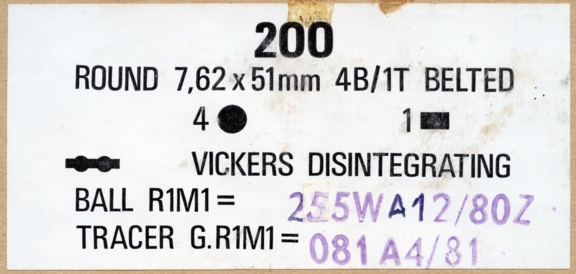

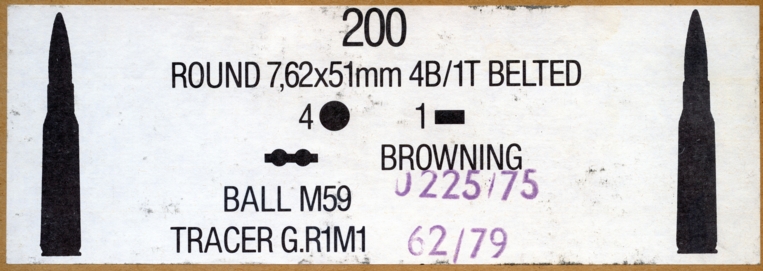

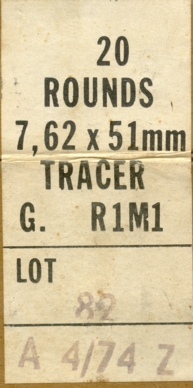

TRACER (1973 – 1981)

Tracer ammunition in South Africa was relatively standard and straight forward. GM bullets were used with one cannelure and a red tip. All cases have a red PA as well as the introduction of the letter “G” denoting tracer. There are a few exceptions namely the second specimen is an A75 headstamp that does not have the red tip colour. Even under magnification there was never any red tip present. The third specimen has a GMCS bullet and is the only one in the whole series. During 1978 the red tip was changed from a lacquered to a more matt red pain as can be seen on the fourth specimen. The last specimen is the A80 case. It used a standard ball case and there is no PA or red tip.

Second specimen has a double primer stab crimp

Second specimen has a double primer stab crimp

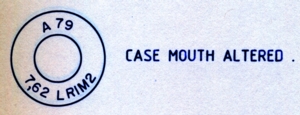

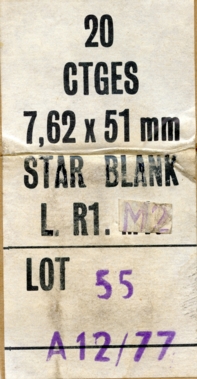

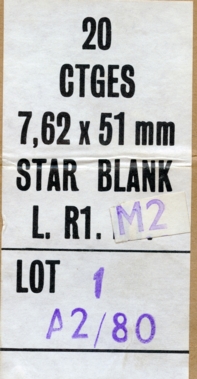

BLANK (1973 – 1982)

There is one significant change regarding RSA manufactured blanks in 1974 and that is the change-over from the M1 to M2 blank. It is only the 1973 production blanks observed as R1M1. The M1 blank used a straight 3-lobe petal crimp whereas the M2 blank utilised a 3-lobe petal crimp with a slight twist to facilitate feeding in the FN-FAL Rifles.For the most part, all specimens have a clear mouth seal and PA.

This is an extract from Sheet 14 of the Manual on Headstamp Markings showing the alteration from M1 to M2.

This is an extract from Sheet 14 of the Manual on Headstamp Markings showing the alteration from M1 to M2.

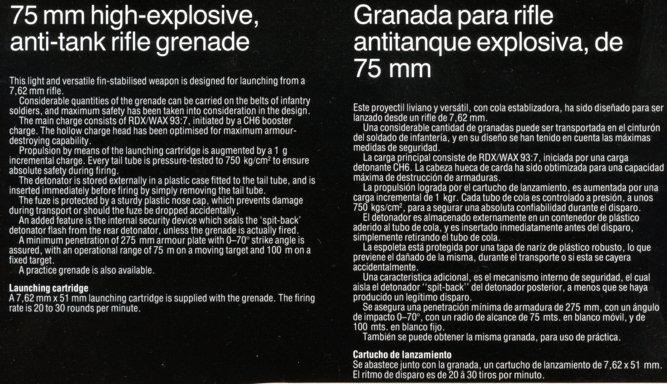

The last two specimens are experimental blanks, not adopted by South Africa, but might have been on contract for a foreign client. The Armscor pamplet shown below for the Grenade blanks show the manual were in Spanish as well, so it might be assumed at this stage that these might have been for a South American client. Spanish is not encountered anywhere in Southern Africa as there were no Spanish colonies, only Portuguese (Mozambique and Angola).

Note the change on the box labels where it was changed to M2 designation.

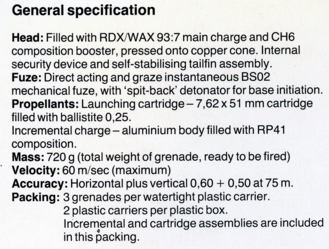

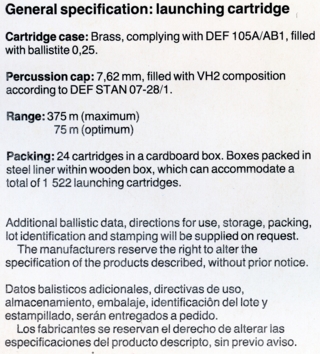

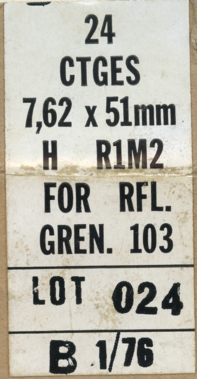

GRENADE BLANK (1973 – 1982)

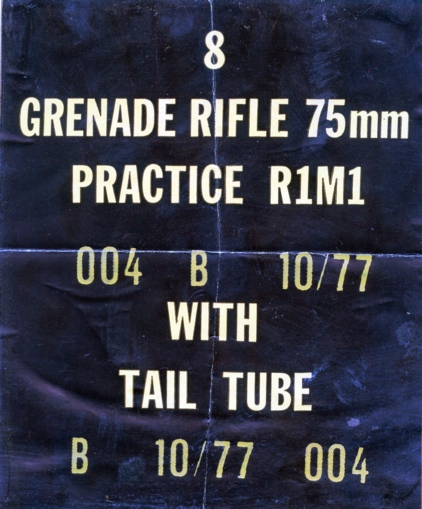

Grenade blank production started in 1973. All cases are brass with a 6 petal crimp and total length of 50.80mm. Case mouth seal is wax, except for one specimen with a white paint seal. Purple PA was utilised until 1977. All cases have black lettering stencilled on the side of the case. There are three types known, namely: 75MM (Anti-Tank), 103 (Anti-Personnel) and 2,23gr. (Unknown, but might have been made for the Rhodesian Armed Forces). There is also the letter “B” (Ballistite), the lot number and the actual date of manufacture. It is interesting to note that the date of manufacturing stencilled on the case does not necessarily coincide with the date on the headstamp. There are no headstamps in the following years: 1975, 1976, 1981 and 1982 although cases were loaded during each of these years. Grenade blanks are identified by the letter “H” on the headstamp.

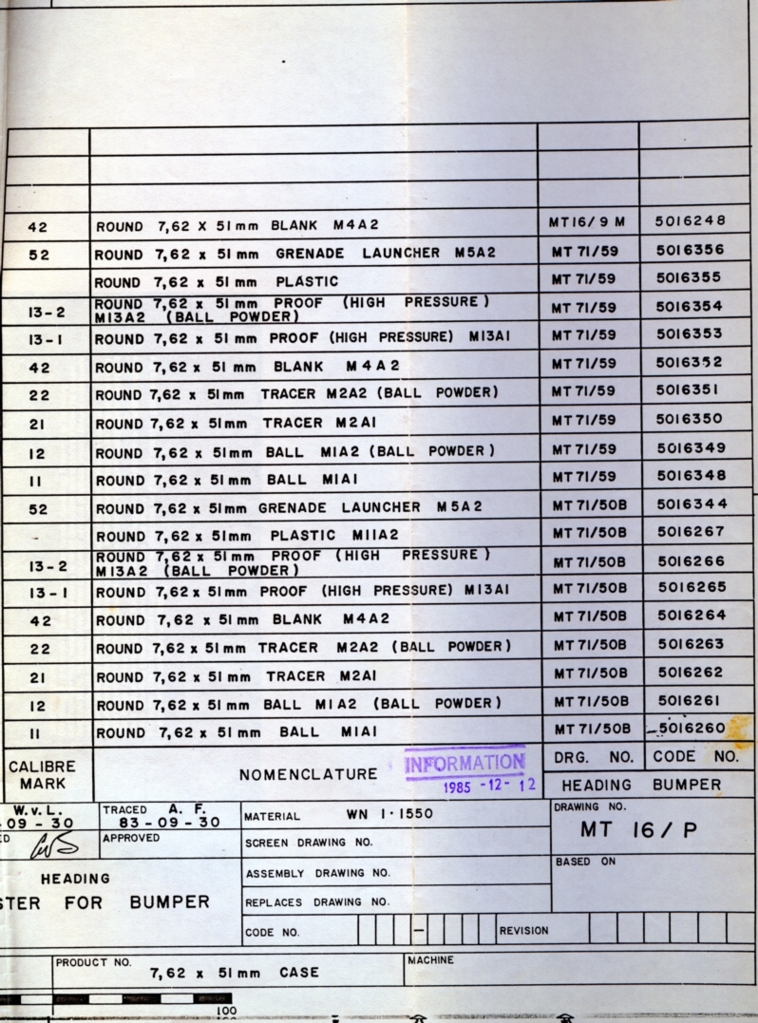

The table below gives an indication of the headstamps with actual date of manufacture of the cartridge:

| 75MM | 103 | 2.23gm. | |

| A73 | 5 B 2/74 | B 10/73 | |

| 6 B 2/74 | |||

| A74 | 77 – B – 3/75 | 030 – B – 2/76 | 001 – B – 4/76 |

| 98 – B – 4/75 | 092 – B – 8/77 | ||

| 111 – B – 6/75 | 110 – B – 10/7? (should be 7) | ||

| 165 – B – 2/7? | 121 – B – 11/77 | ||

| 025 – B – 9/76 | |||

| A77 | 167 – B – 03/78 | 158 – B – 01/78 | |

| 172 – B – 04/78 | |||

| A78 | 189 – B – 08/79 | 195 – B – 08/78 | |

| 238 – B – 05/79 | |||

| A78 | 254 – B – 07/79 | ||

| 260 – B – 07/79 | |||

| A80 | 278 – B – 8/80 | 297 – B – 7/81 | |

| 282 – B – 8/80 | |||

| 295 – B – 8/80 | |||

| 327 – B – 10/82 * White CMS |

Below are 2 pages from Pamphlet 13, showing the designation for the 75mm and 103 Grenade Blanks. It also gives an explanation of the difference between the R1M1 and R1M2 designation. Note that no R1M1 headstamps have been observed yet.

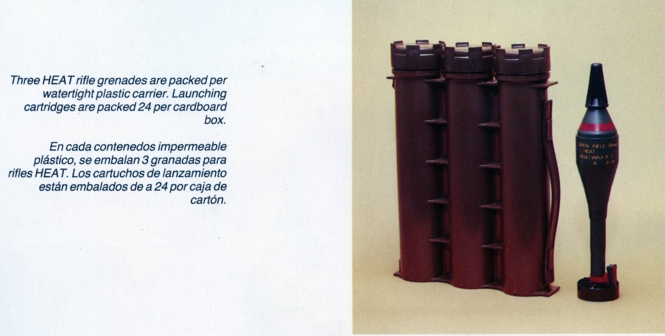

Below are pictures from an old Armscor brochure for the 75mm Grenade. Interesting is the text is also in Spanish.

From the above it shows that the grenades were packed in 3-tube configuration. The crate label below shows that there were 8 of the 3-tube containers, therefore 24 grenades in total. That is why the grenade blanks are packed in boxes of 24 instead of 20 as was standard with other ammunition.

SAFETY (1973 – 1982)

A HUGE thank you to Paul Smith for sectioning this Safety Round!

6X51mm PROOF (1973)

This case resembles the 243 Winchester case, but was intended to be fired in a 7,62 barrel for tumbling tests.

SHORT RANGE (1973 – 1982)

These are the same as for the PMP range with the French orange plastic bullet. None of the blue series has ever been seen on these. Ball cases were used on all specimens, but not all years are represented. There is a difference on the A75 specimen as it has a rebated rim for auto fire training. The rebated rim was to facilitate cycling in the FN rifle.

PROOF (1973 – 1982)

Unlike the PMP versions the A-series warmer proof loads only had the purple base and not the purple tip

The proof loads either had a honey coloured PA or base with honey coloured tip. It is unknown why the A80 version had a matt black base

The A81 version saw the change to a yellow base and tip. It is also the only proof load that had the letter “Q” denoting proof

DUMMY/DRILL (1973 – 1982)

Above specimens all have the two through-holes (low and high) with wooden distance piece

Novelty where the tip was drilled and fitted with a ball point pen

Novelty where the tip was drilled and fitted with a ball point pen

The second specimen has an A76 headstamp and is a belt link test dummy.

The fourth specimen has a CNCS bullet and might have been a display dummy. Case is polished

The second last specimen is not a tracer dummy, but a belt link test dummy with wooden distance piece. The tip has been laquered red to resemble a tracer in a 4 Ball/ 1 Tracer pattern.

SUBSONIC (1976)

Similar to the earlier PMP version. Ball case used with what looks like a copper washed lead bullet. There is a similar 9mmP round that came from a box marked “SUB-SONIC”

ACCELERATOR (1977 – 1980)

I am still looking for information regarding this project

MISCELLANEOUS/UNIDENTIFIED

Drawn case prior to finish

Drawn case prior to finish

Pressure Test

Pressure Test

The following specimens are all on the A77 case

First specimen unknown with normal GM bullet and small cream/white tip

Second specimen rumoured to be for special forces use, probably as a type of safety round. Has a steel ball bearing in the tip

Last three specimens unknown, but rumoured to be for the Rhodesian Armed Forces, but this is speculation only. First one has a GM bullet with red tip and rolled neck crimp. Bullet is not standard Armscor production. Second one has a brownish red and black tip, almost like soviet block API rounds, but bullet is standard GM. Might be some sort of subsonic or otherwise proof load? Last one has a black tip as well as black band. GM Steel Core, probably some form of AP or APHC round.

The A79 above right is a standard tracer load, but tip has a thick white paint cover. This might not be a legitimate round, but some private venture.

STERILE AND SEMI STERILE SERIES (LATE 70’S – MID 80’S)

South Africa was involved in various conflict situations in Southern Africa during the seventies and eighties, (Ian Smith’s Rhodesia, Renamo in Mozambique and Jonas Savimbi’s troops fighting the Cubans in Angola). There was therefore a need to supply ammunition on a clandestine basis to allies. This series consisted of mainly Ball and Tracer.

There are a number of different loadings on these cases, but it is assumed that it was used because of availability and not any specific contractual agreements

unknown, but first specimen might have been a proof loading

unknown, but first specimen might have been a proof loading

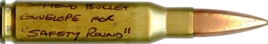

Box label states “Softened bullet envelope for Safety Round”

Box label states “Softened bullet envelope for Safety Round”

novelty key-chain

novelty key-chain

__________

— There is a lot of research still to do and add on the items below, please check in regularly for updates —

Normal Ball loads on unheadstamped cases

Normal Ball loads on unheadstamped cases

Unknown Ball round with large (.303 type) primer and red base.

Unknown Ball round with large (.303 type) primer and red base.

ISRAEL CONTRACT LOADS

There was some collaboration between South Africa and the IDF during the late seventies and eighties. There were contract loads by Israel for South Africa, as well as the A⊕ range, where the box labels were in Hebrew, but manufactured in South Africa for export, in all probabilty to get around UN sanctions.

Short Range

Short Range

AP

AP

__________

Also on normal GM Ball, these are Reference loads.

Also on normal GM Ball, these are Reference loads.

__________

B-KILLER

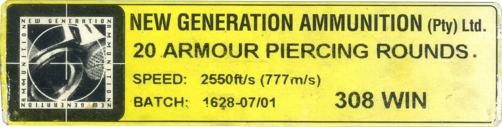

This was an NGA project for a Far Eastern client. The idea was to have a cartridge for snipers and anti-terror units to be able to take out a hijacker though the curved window of an airliner without deflection, hence the name Boeing killer, because NGA used a Boeing window and which was the nickname for this cartridge in South Africa. The resultant bullet used an imported tungsten core inside a copper “sabot” that was manufactured locally. Various versions were tested by NGA.

__________

This is a duplex Glaser load. I will upload the X-Ray soon. Unknown why an RWS case was used.

This is a duplex Glaser load. I will upload the X-Ray soon. Unknown why an RWS case was used.

__________

__________

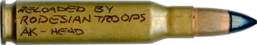

The notes I have on this state that it was loaded by the Rhodesians. They utilised a 7.62×39 API bullet. This is however not confirmed yet, so it might also have been a private venture.

The notes I have on this state that it was loaded by the Rhodesians. They utilised a 7.62×39 API bullet. This is however not confirmed yet, so it might also have been a private venture.

__________

This round resembles one of the police loads. Bullet is of hardened lead.

This round resembles one of the police loads. Bullet is of hardened lead.

__________

This is the K-Bullet that was an experimental design by Ing. Böhm at Hirtenberg during 1986/87. It is a full brass jacketed bullet with flat tip. Apparently it was not successful as a loading in the 7.62 Nato, but according to Heinrich Kohlmann in ECRA bulletin 317-11 (Oct. 91) the K-Bullet was loaded in the 300 Win Mag with much better results. It was rumoured to be a police development for an unknown client. It is possible that it was for South Africa, because the K-Bullet is also found loaded on RSA cases (see below on the Post 83 Series). The K-Bullet was a stepping stone for the ABC Bullet.

This is the ABC Bullet referred to above. Apparently much better ballistics were achieved with this bullet.

__________

Ordinary Ball loadings on Spanish and Portuguese cases

Ordinary Ball loadings on Spanish and Portuguese cases

Similar to the SAKO round above, this is the 7.62×39 API bullet apparently loaded by Rhodesia.

Similar to the SAKO round above, this is the 7.62×39 API bullet apparently loaded by Rhodesia.

__________

Dim Ignition tracer for a foreign client.

Dim Ignition tracer for a foreign client.

Ball (Purple PA) and Tracer (Red PA)

Ball (Purple PA) and Tracer (Red PA)

Ball (Purple PA) and Tracer (Red PA)

Ball (Purple PA) and Tracer (Red PA)

AP-I loaded for a foreign client

AP-I loaded for a foreign client

__________

Contract cases for a foreign client

Contract cases for a foreign client

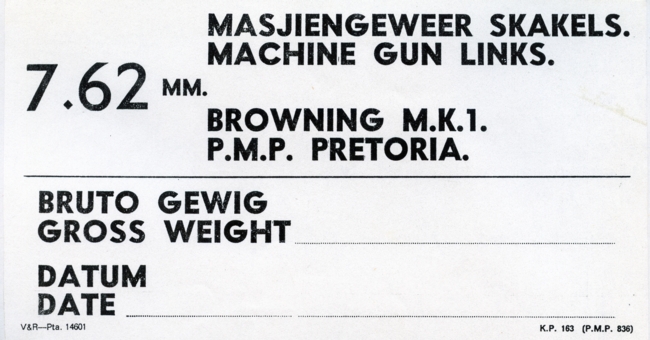

LA SERIES (1977 – 1979)

The LA series was used for a period between 1977 to 1979. The “L” was in honour of one of the employees at the Armscor factory (Mr. Luther). The reason for the change was simply that the cases were manufactured by a different drawing process. The attached sheet is part of a booklet denoting headstamp markings on RSA ammunition. Although the list showed a date of 1972, the LA series was only made from 1977 (2 different bunters) to 1979, with brass and copper primer and normal GM bullet.

BALL

_______________

SHORT RANGE

Utilised the same orange plastic bullet as the PMP series. Two dates are known, namely 1977 and 1978

_______________

TRACER

There is no remnant of colour on the tip

There is no remnant of colour on the tip

_______________

DUMMY

_______________

PROOF

WA SERIES (1979 – 1980)

As with the LA series, the WA series was named after Mr. Walther, one of the employees at the Armscor plant. The reason for the change in headstamp was also because a different drawing process was used. Although the data sheet states that the WA series was made until 1982, no headstamps beyond 1980 have been examined.

BALL

Unfinished draw piece

Unfinished draw piece

____________

DUMMY

Strong segmented mouth crimp

Strong segmented mouth crimp

B SERIES (1981 – 1982)

BALL

_______________

TRACER

_______________

SHORT RANGE

_______________

MATCH

_______________

SAFETY

Soft brass jacket with Plaster of Paris core. The goal was to prevent over-penetration of targets and harming innocent bystanders.

_______________

DRILL

_______________

DUMMY

A (NATO CONTRACT) SERIES (1974 – 1975)

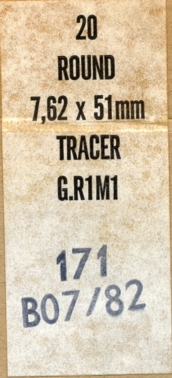

There is some speculation regarding this headstamp. It was done by South Africa as an export contract and these cartridges may or may not have been manufactured up to NATO standard. There are unconfirmed reports that the outer containers were marked in Hebrew. The box label is as follows:

20

RND 7.62mm

BALL M59

A LOT 116 – 74

Although the label states that the bullet was an M59 (steel core), it is in actual fact a standard M80 (GM) bullet. There are reports that an A ⊕ 76 version also exists, but that has not been confirmed. Only Ball rounds have been examined, there was no tracer or any other loadings in this headstamp variation. (IAA Forum)

POST 1983 SERIES

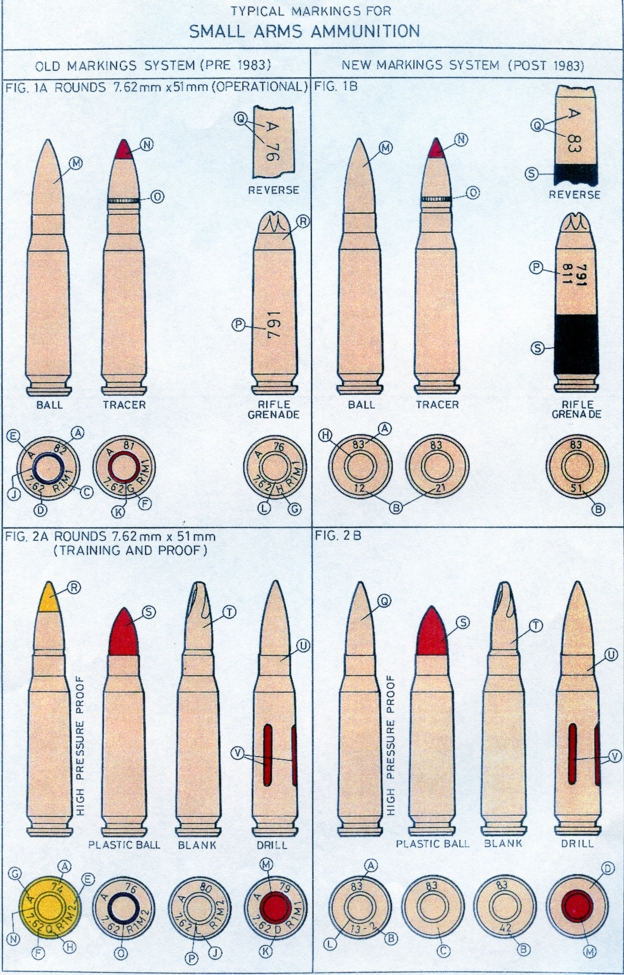

1983 saw the most significant change in ammunition manufacture in South Africa. This change affected the whole spectrum of ammunition manufacturing, from small arms ammunition up to naval ammunition. Medium, large and Naval ammunition falls outside the scope of this project, but for small arms the changes were that all markings were simplified to a year of manufacture and an abbreviated model number that replaced the old manufacturer monogram, year, caliber, model and code letter that denoted the role of ammunition used. The following is from the booklet dealing with the changes from the pre 1983 to the post 1983 system.

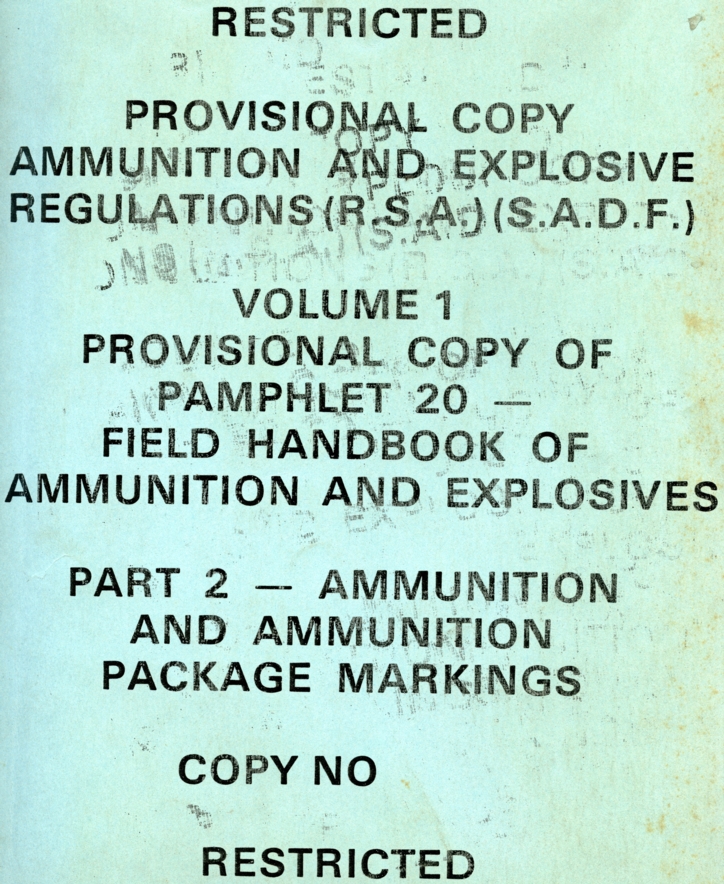

This is a copy of Pamplet 20, which is the main description of the change-over in 1983. The text is reproduced below:

This is a copy of Pamplet 20, which is the main description of the change-over in 1983. The text is reproduced below:

RESTRICTED

101

FIELD HANDBOOK OF AMMUNITION AND EXPLOSIVES

PART 2 – AMMUNITION AND AMMUNITION PACKAGE MARKINGS

CHAPTER 1 – FOREWORD

1. This handbook is designed to help the User identify ammunition, quickly and accurately, under field conditions.

SCOPE

2. It covers ammunition marked in the BSA, or marked overseas to RSA specifications. It does not cover imported ammunition marked to foreign specifications.

3. It covers the Pre 1983 and Post 1983 RSA ammunition markings systems .

ASSOCIATE PUBLICATIONS

4. Full details of the Pre 1983 system are given in “Joint Service Ammunition and Ammunition Package Markings”, a British publication on limited issue in the RSA.

5. A full technical manual is being prepared to cover the Post 1983 system.

6. This handbook gives a digest of the two systems for the benefit of the User.

BACKGROUND

7. The Pre 1983 RSA System Prior to 1983 ammunition was marked in accordance with a system the British introduced in 1960 and discontinued in 1969. The British changed their system partly because it became cluttered up with amendments, but mainly to conform to NATO specifications, which introduced a unified and simple system of colour coding to allow rapid identification of‘ ammunition by personnel of varied nationalities.

8. The RSA continued to use the British system after the British themselves had abandoned it, and RSA amendments and deviations were added. A point was reached where the system no longer met present day needs and a new RSA ammunition markings system was required.

9. The Post 1983 RSA System The NATO ammunition marking system has the advantages of clarity and simplicity and it was decided to introduce an RSA version which followed the NATO systems principals but which embodied alterations designed to meet RSA conditions.

10. The main changes introduced under the post 1983 system are as follows:

a. The pre 1983 system enforced rigid colour coding to indicate the “type” of ammunition, eg Dark Green = HE, Light Green = Smoke.

b. The post 1983 system uses a similar colour code but allows the use of alternative colours for camouflage, or other operational reasons, if the User requires this. These alternative colours have no meaning under the marking system and are called “non-significant colours” .

c. Where non-significant colours are used a system of coloured bands ere superimposed to indicate:

i. “Role” or “Target Effect”. eg Armour Defeating.

ii. “Hazard”, eg High Explosive Hazard or Low Explosive Hazard.

d. The pre 1983 use of the “red filling ring” to indicate the presence of an explosive filling or active agent is discontinued.

11. Further detail is given in Chapters 2 and 3. Examples of markings under the pre 1983 and post 1983 systems ere compared in the plates included in this handbook.

CHAPTER 2 – THE COLOUR CODING OF AMMUNITION

This chapter deals with the colour coding of mainly medium and large caliber ammunition and is not discussed here

CHAPTER 3 – MAIN IDENTIFICATION DETAILS

This chapter deals with filling codes, model numbers as well as lotting and batching, again medium and large caliber

CHAPTER 4 – 20MM, 30MM AND 35MM ROUNDS

Not discussed

CHAPTER 5 – SMALL ARMS AMMUNITION

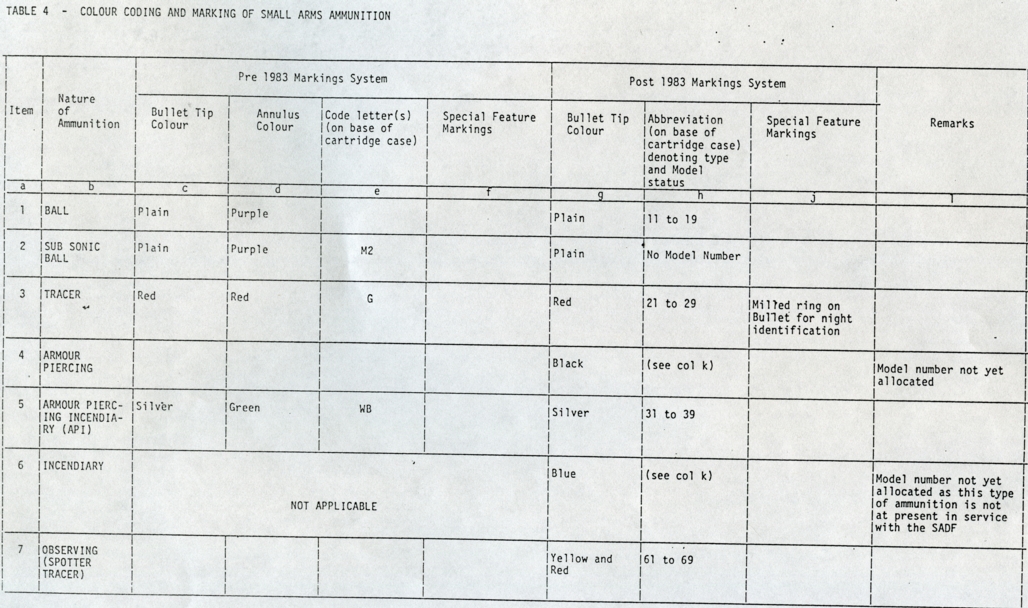

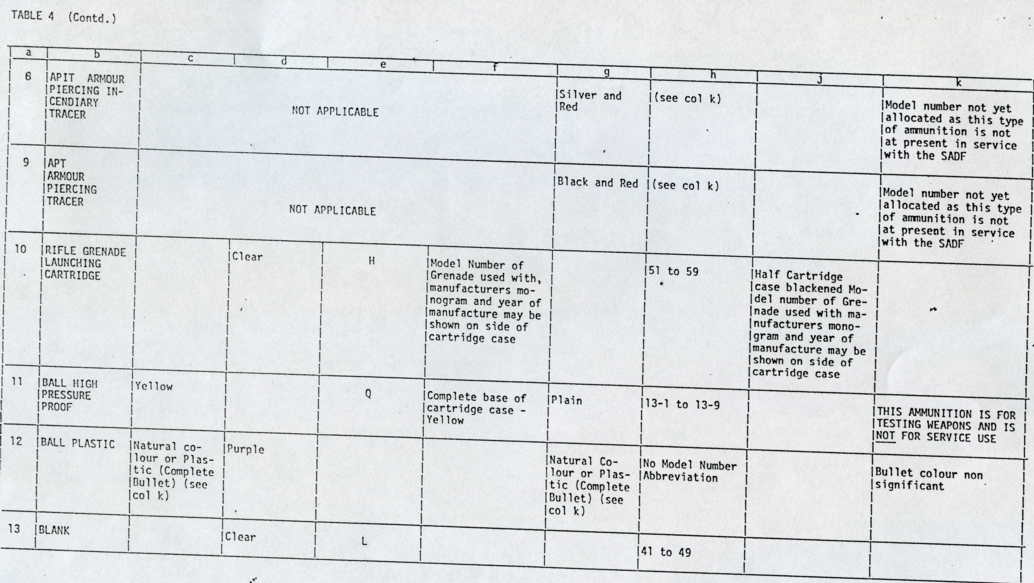

ROLE IDENTIFICATION MARKINGS

1. Prior to 1983 differing roles of Small Arms Ammunition (eg. Ball, Blank, Tracer, etc.) were identified by the following means:

a. Bullet tip colour

b. Annulus colour

c. Code letter on the base of the cartridge case.

2. Under the post 1983 markings system the role of Small Arms Ammunition is identified by:

a. Bullet tip colour

b. Abbreviated model number on the base of the cartridge case.

3. The Annulus colour under the post 1983 markings system has no significance.

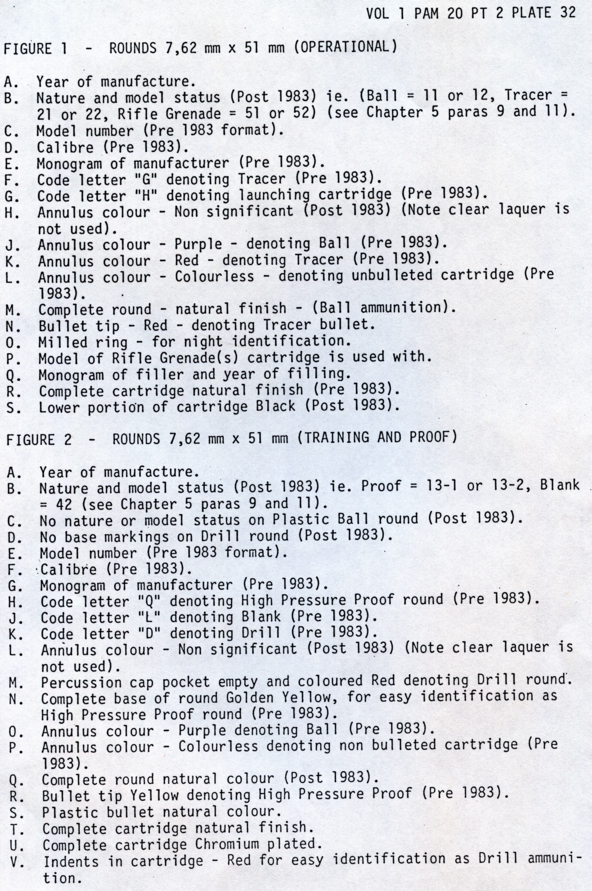

4. The significance of bullet tip, annulus colours and code letters under the Pre I983, and Post l983, systems is described in Table 4.

CARTRIDGE CASE BASE MARKINGS

5. Prior to 1983 the following information was stamped on a cartridge case base:

a. Monogram of manufacturer

b. The year of manufacture

c. The calibre

d. The model number

e. A code letter denoting the role of ammunition (not applicable to Ball ammunition)

6. with the introduction of the Post 1983 marking system the base markings are simplified to:

a. Year of manufacture

b. The abbreviated model number.

7. On ammunition with similar physical dimensions (eg. 9 mm x 19 and 9,65 mm x 19,5) the calibre may also be marked in addition to the year of manufacture and abbreviated model number.

MODEL NUMBER (POST 1983 MARKINGS SYSTEM)

8. Small Arms Ammunition model numbers, with the implementation of the Post 1983 markings system, follow the same basic format as described in Chapter 2 para 4. (Where “role” and “hazard” co-incide, for example with some HE filled items, a double band of the appropriate colour is used.).

9. The first numeral of the model number is used to denote the role of the ammunition, and is shown as follows:

a. Ball = M1 Series (eg. M1A1, M1A2 etc.)

b. Tracer = M2 Series (eg. M2A1, M2A2, etc.)

c. Armour-Piercing Incendiary = M3 Series (eg. M3A2, M3A3, etc.)

d. Blank = M4 Series (eg. M4A1, M4A2, etc.)

e. Rifle Grenade Launching Cartridge = M5 Series leg. M5A1, M5A2, etc.)

f. Observing (Spotter-Tracer ) = H6 Series (eg. M6A1)

g. Subsonic Ball = M10 Series (eg. M10A1)

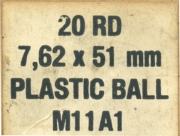

h. Plastic Ball = M11 Series (eg. M11A1)

j. Ball Safety = M12 Series

k. High Pressure Proof = M13 Series (eg. M13A1, M13A2 etc.)

l. Drill = H14 Series

10. M7, 8, and 9 series will be allocated to other types of ammunition (eg. Incendiary, Armour Piercing} if these become applicable at a future date.

ABBREVIATED MODEL NUMBERS

11. To aid simplicity and economy in the markings process, the model number stamped on the base of the cartridge case is reduced to the two significant and changeable numerals in the model number format, the constant “M” and “A” letter not being shown. (eg. M1A1 is shown as 11, M1A2 is shown as 12, M2A2 is shown as 22, M3A3 is shown as 33, etc.)

AMMUNITION WITH DUAL ROLES

12. Ammunition with Dual Roles (eg. Spotter Tracer) has the bullet tip colour appropriate to the primary role, followed by a coloured band appropriate to the secondary role. Thus Spotter Tracer would have a yellow bullet tip (denoting a primary role of Observing), followed by a red band (denoting a secondary role of Tracer). Armour Piercing Incendiary Tracer (APIT) would have a silver bullet tip (denoting a primary role of Armour Piercing Incendiary) followed by a red band (denoting a secondary role of Tracer.)

CHAPTER 6 – NAVAL AMMUNITION

Not discussed here

CHAPTER 7 – AMMUNITION PACKAGE MARKINGS

To follow, together with Figures 1 – 3

TABLE 1 Colour coding of ammunition land and air service (other than S.A.A. and Projectiles 35mm and below) – not discussed

TABLE 2 Colour coding of Naval Ammunition (other than S.A.A. and Projectiles 35mm and below) – not discussed

TABLE 3 Colour coding of 20mm, 30mm and 35mm Ammunition – not discussed

TABLE 4 Colour coding and marking of small arms ammunition

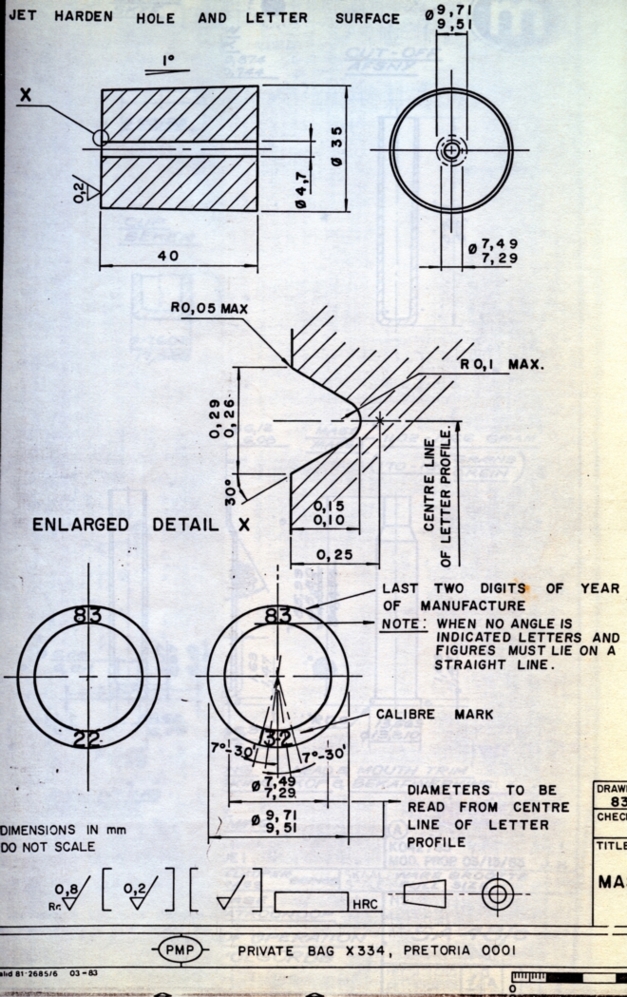

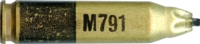

Above is the technical drawing for the bunter on the new Post 83 Series.

BALL

Odd because M5A2 should be grenade blank?

Odd because M5A2 should be grenade blank?

M1A4 = BOXER PRIMED

M1A4 = BOXER PRIMED

TRACER

BLANK

GRENADE BLANK

This was an experimental grenade blank for launching CS Gas cannisters

This was an experimental grenade blank for launching CS Gas cannisters

GRENADE BLANK (CS GAS)

PRIMER SENSITIVITY TEST

Primer sensitivity test using unfinished blank cases

Primer sensitivity test using unfinished blank cases

DUMMY/DRILL

Unknown why the second specimen has a black base. The last specimen is a TRACER case (M2A3) but was loaded with ordinary GM bullet

WEIGHT TEST DUMMY

TRACER DUMMY

Fourth specimen utilised a ball case (M1A3)

PROOF

This is the only version examined from the “NEW” series with the honey coloured tip.

This specimen has a light coloured lilac p/a. It is possible that it might have been used at Lyttleton Engineering works.

All the specimens below have a GM yellow coloured tip. The first specimen “86 13-2” can also be found without tip colour. The last specimen is a tracer case, namely M2A3. The red PA can be seen under the yellow base colour.

ACCELERATOR

One specimen has been examined on a tracer case (M2A1). It uses a 5.56mm Monad bullet in a clear sabot

HIGH PRESSURE TEST

SHORT RANGE

PRESSURE TEST

BUTTER

The first specimen is a “standard” butter round. It was designed as a short range cartridge with limited penetration/high wounding factor, for hostage situations. The second specimen is something new we encountered. It consists of a lead base, with nylon filler and aluminium tip in a GM jacket. There has not been any reference material about this specific design. Once again a big thank you to Paul Smith for sectioning this round.

SAFETY ROUND

The first specimen has a red base and the second specimen has a red base, except for the primer. It might indicate different loadings. The bullet ogive differs on the two specimens.

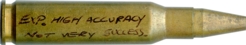

MATCH LOAD/HIGH ACCURACY

I cannot find any specific info on this round, so it might be a private venture and not something the SADF did.

I cannot find any specific info on this round, so it might be a private venture and not something the SADF did.

BISLEY

MONAD

APHC

AP Hard Core. Bullets are slightly magnetic. First specimen has a different bullet profile.

These might have been some experimental project on a foreign contract.

These might have been some experimental project on a foreign contract.

ARMOR PIERCING

This is a display dummy. AP ammunition was not produced in South Africa, except for export.

CORE MATERIAL TEST

I am still trying to get more information on this project. Only one case was used namely 1988 M1A2

1. Dummy load, orange plastic “core”, not loaded

2. Brass core

3. Lead sleeve with tungsten core

4. Dark green sleeve, steel/tungsten? core

5. Green sleeve, tungsten core

6. Green sleeve, steel/tungsten? core

7. Green sleeve, steel/tungsten? core

8. Short green sleeve, steel/tungsten? core

9. Yellow sleeve, brass core (non magnetic)

10. Yellow sleeve, tungsten core

OTHER

Cartridge has a chamferred rim and wider extraction groove. It is not known for what purpose.

This might be some sort of proof round, but not confirmed. Rim resembles Norma proof loads. In the RSACCA newsletter 194 (3 of 2000) p.6 it is stated via Erlen Meyer that these came from the Transkei Police Armory. Transkei was one of the independent homelands in the south-eastern corner of the country that were all absorbed back into the Republic of South Africa after 1994.

Note with the cartridge states that it was for game rangers in the Kruger National Park for following up on wounded/poached elephant. Most rangers carry either 375H&H or 458 Win, so these might have been for the military patrols, but again no substantiated evidence. The note also states that these were manufactured from US WW2 30-06 AP. I will still classify this as unknown or maybe a private reload until there is evidence to the contrary.

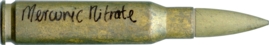

Interesting “PROOF” round. A specimen is immersed in a mercuric nitrate solution. Case is then inspected for flaws and irregularities.

LYTTLETON ENGINEERING WORKS

MUSGRAVE

These cartridges were loaded in Austria by Hirtenberg during the sanction years.

PMP COMMERCIAL

These cases follow on from the PMP dated series. The last dated PMP commercial case was in 1969 and in 1970 the date was replaced by the commercial version of the headstamp. PMP Commercial loadings consisted of GM SP bullets in 150gr, 168gr and 180gr. versions. Ball loadings were also made on commercial brass with a 147gr. loading. Match loads varied between 143gr – 168gr.

These have no dots in the headstamp. First two specimens are proof loads

These have no dots in the headstamp. First two specimens are proof loads

Third specimen has the light copper primer cup. Last version is a match load.

Third specimen has the light copper primer cup. Last version is a match load.

__________

The two specimens below are “intermediate” type headstamps for the change over during the early 1980’s

__________

First specimen is a dummy, second is with brass primer cup and third version with light copper primer cup.

First specimen is a dummy, second is with brass primer cup and third version with light copper primer cup.

There were a number of military loadings that was still done on these cases.

1. Flak Jacket Test round. Slightly magnetic and resembles an AP round with double cannelure

2. Accelerator, GM with clear sabot

3. Accuracy test

4. Accuracy test

5. Accuracy test

6. Safety round, GM envelope with Plaster of Paris filling

7. Safety round, GM envelope, hollow point

8. B-Killer

9. B-Killer

10. Helmet Test. Short black plastic sabot with two side slits containing a small steel “slug”. It was developed at NGA to simulate shrapnel damage to helmets, but the project was shelved. Apparently the final system utilised a .22cal. blank in a seperate barrel assembly.

11. Helmet Test. Same as above round.

Monad.

Monad.

Proof loads with GM Ball

Proof loads with GM Ball

Unknown. Bullet is magnetic

Unknown. Bullet is magnetic

Safety round shown at 200% scale. It seems the top part of the core is hollow with the tip supposed to collapse quicker on impact, thus limiting penetration.

Safety round shown at 200% scale. It seems the top part of the core is hollow with the tip supposed to collapse quicker on impact, thus limiting penetration.

__________

Same headstamp as above, but with unusual size primer.

Same headstamp as above, but with unusual size primer.

Blackened case dummy with GM Match bullet

Blackened case dummy with GM Match bullet

HPT loading with GM SP bullet

HPT loading with GM SP bullet

1. Glaser Safety round

2. Butter

3. Helmet Test

Comparison of the two types of Monad bullets on this series.

Comparison of the two types of Monad bullets on this series.

Headstamp error on 30-06 case

Headstamp error on 30-06 case

__________

R1M2 blank with turned closure.

R1M2 blank with turned closure.

The ballistic cartridge for launching anti-riot grenades with multiple CS canisters for use with the MUSLER (Republic Arms) 12 bore pump action riot gun.

The anti-riot grenade consists of a head, an adaptor and a launcher tube that fits directly onto the muzzle of the shotgun barrel. The grenade is fired by means of a ballistic cartridge, which, upon firing, initiated the delay mechanism. After a preset delay (10 to 30 seconds) interval the three metal canisters contained in the head are ignited and expelled, each generating a dense cloud of CS irritant smoke. After ejection the spent grenade falls to the ground first whilst the canisters continue forward to the point of aim.

For use in the control of rioters where close contact is to be avoided. The anti-riot grenade can be accurately deployed over distances from 50 to 120 meters, and can also be fired through windows of buildings if required. The three canisters provide CS smoke over a large area and make smothering or ‘throw-back’ more difficult. The irritant anti-riot grenade makes obsolete the ‘shooting-cup’ method of deploying grenades and ensures control of both range and direction. Since the barrel is not obstructed with a ‘shooting-cup’, other ammunition can be fired immediately after launching the grenade.

The body of this initial prototype cartridge assembly is made of turned plastic. A 7.62×51 blank is inserted from the rear. The rose crimp and primed (3 stab crimp) is lacquered red. To improve the seal on the rose crimp a thin cylindrical rubber piece has been crimped into the center of it.

This was one of the very first blanks made for these turned plastic 12 ga. cases. This particular blank had no rubber insert in the rose crimp, no red lacquer seal and the primer was uncrimped.

This was one of the very first blanks made for these turned plastic 12 ga. cases. This particular blank had no rubber insert in the rose crimp, no red lacquer seal and the primer was uncrimped.

__________

MATCH

Match case pressure test

Match case pressure test

PALMA MATCH

__________

Impala (LWHV) Light Weight High Velocity

Impala (LWHV) Light Weight High Velocity

__________

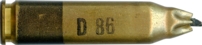

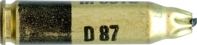

2015 saw a major change in the headstamp style. The PMP has been replaced by D (Denel). Commercial ammunition observed all have the new headstamp, although the brown (PMP) and blue (PMP Pro-Amm) boxes are still unchanged.

OTHER COMMERCIAL

Red anodised dummy by Thor Engineering.

Red anodised dummy by Thor Engineering.