303 BRITISH (SOUTH AFRICA)

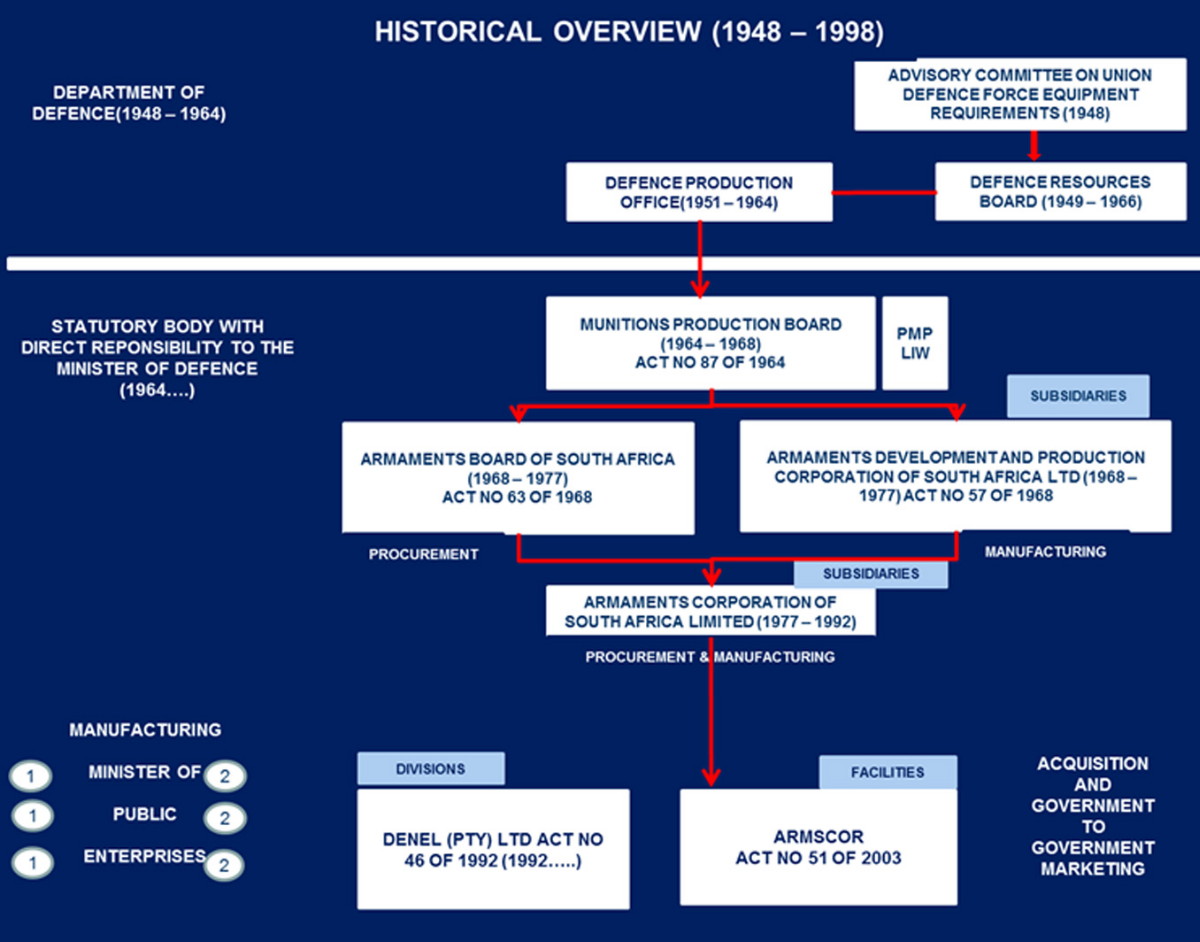

HISTORY

When the Union of South Africa abandoned the gold standard at the end of 1932, the Royal Mint in Pretoria was reduced to moderate activity in the manufacture of silver and bronze coins, though its work continued to expand in the production of medals and badges and special items of a commemorative nature for learned societies, governmental and municipal authorities, Masonic and sporting bodies. During the latter part of 1936 and the beginning of 1937, following discussions with the Defence Department and Treasury of the Union Government to reorganize the armed forces and their equipment, it provided an opportunity in 1937 to approach the then Minister of Defence, Oswald Pirow, K.C., with the suggestion that some of the plant of the Mint – particularly its furnaces and rolling mills – and the experience of its staff in work requiring great accuracy could contribute to the production of certain types of ammunition, notably .303 ammunition, including cap and case loading and also that a proofing department be set up by the Union Defence Force. Certain engineering and operative staff were despatched to the Imperial Chemical Industries plant in Birmingham for training and in early 1938 an engineer and a works manager, on loan by I.C.I., were able to assist in erecting and setting up the plant and guide the local staff in the first production of ammunition ever made in a Government Mint in South Africa.

General Smuts’ visit to the S.A. Mint Ammunition Factory.

The process was not an easy one as was quoted in the notes of The History of the Institute of Mechanical Engineers of South Africa, ‘Ammunition produced first at the Mint at Pretoria and subsequently at a special plant at Kimberly probably had the greatest impact on engineering knowledge of mass production techniques in South Africa. Before the War there existed in this country only three fully automatic lathes, each being a single spindle. Toolroom techniques in the sense known overseas was virtually unknown here and it was a rare occurrence to find in a South African factory any knowledge of the use of slip gauges, or optical measurement or of the basic principles of metrology’. The factory commenced producing .303” Mk.7 ball cartridges in August. 1938 and by December 1938, 4 100 340 cartridges had been delivered to the Defence Department. Suitable buildings for a loading field away from the central Mint were also erected. The site, which was approved by the Defence Department, was on a hillock on the south side of Pretoria adjacent to the Defence Department’s grand magazine and ammunition-testing rifle-range and demolition site, and where railway-siding facilities could be made available without difficulty. The Pretoria factory was only a temporary arrangement for negotiations were under way for the takeover of the Royal Mint by the South African Government. This became a reality early in 1940 when the Royal Mint became the South African Mint and continued operating in Pretoria until early in 1942, when the plant was transferred to Kimberly to supplement the output of the small arms factory which had been operating there since September 1941.

Visit by His Excellency the Governor-General, Sir Patrick Duncan, to the S.A. Mint Ammunition Factory,

At first the Mint in Pretoria produced ball ammunition at the target rate of twelve million rounds per annum, but an extension of the output to include a wider variety of ordnance was decided on early in 1939 and on the outbreak of hostilities in Europe was immediately approved. These extensions included artillery cases for up to 4.5” Howitzer, 18- and 25-pounder shell cases, anti-tank solid steel shot, several types of primers, fuses, detonators, etc., flame tracer and armor piercing .303” small arms ammunition. It became clear however when the target rate for .303 ammunition was changed to unlimited output that the Pretoria facilities were inadequate for wartime production. A meeting was held, chaired by General Smuts, and attended by Dr. P.V van de Bijl, a member of the Smuts Cabinet and at that stage the minister for Native Affairs, Mr. T.P. Becklake. Deputy Master of the old Royal Mint and first director of the SA Mint, and civil engineer, Mr. Kingsley “Carlie” Carlstein, who was to be appointed as the manager of the new facility and who later became the Director of the Kimberley Engineering Works. As a result of this meeting, Mr. Stratten, who was the Chairman of the Union Corporation and Mr. Carlstein visited Kimberly to ascertain the extent of production facilities and the decision was made to relocate the factory entirely to Kimberley, which had been in operation since September 1941.

The plant was operating in the Kimberly tram sheds that were adjacent to the well-equipped workshops of the de Beers Diamond Company. The existing factory in Kimberley was originally destined for France from the United States on a lend-lease basis, but when France fell to the Germans in early 1940 it was diverted to South Africa. The reasoning for the move to Kimberley was three-fold, firstly to spread the risk in case of an attack, secondly because of the existing rail and road infrastructure network already in place from the diamond mining days and thirdly to address the critical shortage of labour and housing facilities in Pretoria, whereas the area surrounding Kimberley had sufficient labour available. Skilled staff for the Mint were supplied by such bodies as the Chamber of Mines and large South African engineering and manufacturing concerns and apart from these, the Mint employed almost 14,300 people during the War. The original Pretoria plant was kept in operation until early in 1942 and was then transferred and the factory was known as the South African Mint – Kimberly Branch and functioned from September 1941 until about September 1945. The only type of small arms ammunition made in South Africa during World War II was .303” ammunition and interesting to note that only the components and not loaded ammunition were manufactured at Kimberley. Bullets and cases were on completion sent to a central loading facility in Pretoria. Production was almost brought to a halt when an explosion occurred in the early hours of the1st of March 1945 in the neighboring grand magazine of the Defense Department in Pretoria with twenty-six dead and two hundred and eighty-nine injured. The buildings and plant were damaged to such an extent as to reduce the loading production of .303 small arms ammunition by 75%.

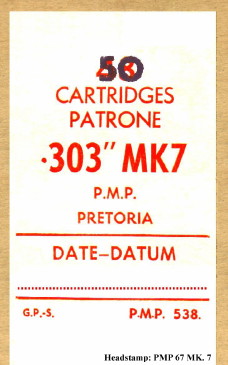

The total wartime production of .303” ammunition in South Africa was almost seven hundred and sixty million rounds (759 066 199). By end of the war, the SA Mint was operating 6 munitions factories; three were in Pretoria, one in Johannesburg, one in Ladysmith and one in Kimberly, manufacturing a wide variety of munitions. The decision was taken to discontinue the manufacturing of all the various munitions except .303” cartridges and that the factory, for their continued manufacture, would be centralized in Pretoria at the site of the current PMP factory to the west of Pretoria, which was then known as the South African Mint – Ammunition Branch. Small scale production was restarted late in 1946. As from the 1st of December 1964, the factory was placed under the control of the Armaments Board and its designation changed to Pretoria West Metal Pressings. In about June 1965 the SAM headstamp was replaced with PMP. In October 1968 the Factory was placed under the control of the newly formed Armaments Development and Production Corporation (Armscor) and was redesignated Pretoria Metal Pressings (Pty.) Ltd.

Sources:

Becklake, J.T. From Real to Rand: The Story of Money, Medals and Mints in South Africa. Published by the Central New Agency, Ltd., South Africa, 1963.

Shaw, DH. SOUTH AFRICAN .303” (British) Headstamps. The Journal of the Historical Firearms Society of South Africa, Dec.1972, Pg.4

Nell, L.D. 2002 .303” Berdan Primers Manufactured at Modderfontein, Johannesburg. unpublished notes

Correspondence between collector Mr. M. Donaldson, (Umfolozi Game Reserve, Mtubatuba, Zululand) and Mr. D. H. Shaw (Manager at PMP) dated 15th June 1971 & 27th July 1971. Mr. Shaw was chiefly responsible for the installation and commissioning of the Kimberley plant and was then appointed Assistant Works Manager, a position he held from September 1941, until February 1945, when he was transferred as manager to the Ladysmith (Natal) Branch of the S.A. Mint, and later Manager of Pretoria Metal Pressings.

Huson, P. THE KIMBERLY MINT. unpublished notes

Labbet P. & Mead P.J.F .303 Inch – A History of the .303 Cartridge in British Service, 1988. Braun-Brumfield, Ann Arbor, MI USA, ISBN-0-9512922-0-X.

Munnery J. 1983. Correspondence with Arno Klee from The RSA Cartridge Collectors Association regarding Armor Piercing ammunition development in South Africa from 1940 – 1944.

MILITARY VARIATIONS

CALIBRATION TESTING OF EQUIPMENT

The specimens below (K37 VII and K38 VII) are still found in many South African collections today. The ones listed here were originally from the estate of former SADF officer Trap Pelser, who was responsible for small arms testing and procurement for the SADF. The notes state that these cartridges were “Loaded in Pretoria” and were included among a few South African rounds with U 38 VII headstamp. From visual inspection the South African specimens are the same as the British versions. Disassembled rounds also show that the glazed board wads and cordite were similar to the British cartridges, except for the bullets, which had a raised ‘U’ as opposed to the British specimens which had a raised ‘K’, all bullets being GMCS. It is speculated that some of the tooling equipment or components at least were sent from Britain to South Africa to assist with testing and calibrating of the loading facilities in Pretoria.

As can be seen from the specimens above shown at 150% scale, both have distinct punch markings on the date. As this was the first time that any type of small arms ammunition was manufactured in South Africa, it may have been done to test the bunter strike depth and orientation as the date markings on the headstamp are faint and indistinct as opposed to the mark number. On the list of South African headstamps listed below, only one specimen (U.38 VII) was found with a period mark on the headstamp. All subsequent dates had the period omitted.

A few South African specimens are found with cupro-nickel envelopes. These were British and were loaded in South African cases, in all probability as some form of calibration or reference loading.

The U (for Union of South Africa) was standardised for use on all .303” ammunition manufactured in South Africa together with the date and standard purple primer annulus. South Africa followed the British system where the model/mark number was added at the bottom of the headstamp as VII in the case of the Mark 7 and this practice continued until the end of the War in 1945. With the relocation of the factory to Kimberley it was decided to add a stylized diamond to the headstamp between the U and the date. Early production bullets were Gilding Metal Clad Steel, but due to the scarcity of suitable steel during the War period the bullet envelopes were changed to Gilding Metal only during mid-1942.

BALL AMMUNITION

The reason for the period before the date is unknown. It is also the only time it was used.

The reason for the period before the date is unknown. It is also the only time it was used.

As can be seen on the versions from 1939 and 1941, there were a variety of different variations. Early bullets had a GMCS envelope, but wartime necessities forced a change to GM only from 1942 onwards.

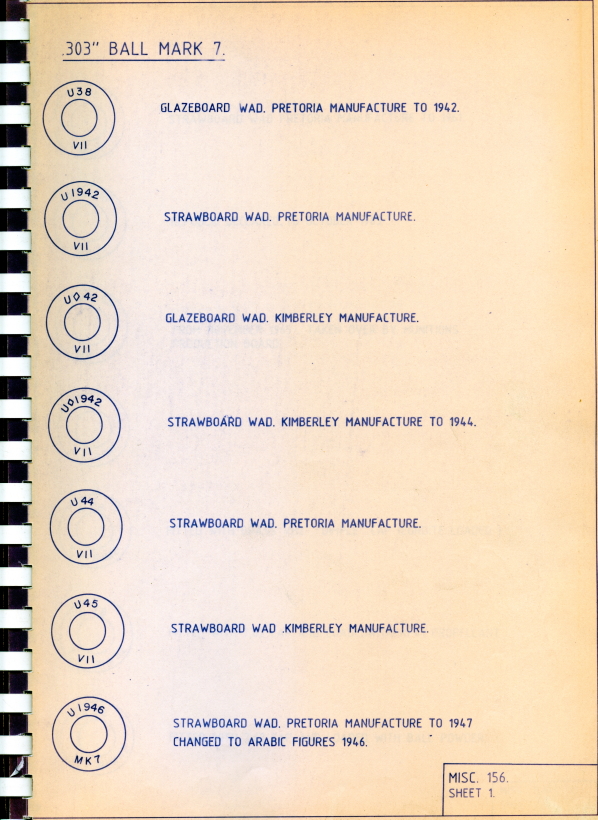

During the early years of the War, some of the older aircraft were still fabric covered and utilised synchronised guns to fire through the propellers of the aircraft. It was found that the glazed board wad used did not disintegrate on firing and it caused damage to the aeroplane propellers and bodies.The softer strawboard wads, which did disintegrate on firing, were therefore introduced for ammunition intended for aircraft use and was later generally adopted. A two-digit date headstamp style indicates the use of glazed-board wads (i.e. U 38 VII) whereas a four-digit date headstamp style denotes the use of strawboard wads (i.e. U 1942 VII or U ◊ 1942 VII). However, by 1944 strawboard wads had been standardized throughout the .303” ammunition range, even though the headstamp bore the two-digit date style (i.e. U 44 VII).

| DATE | BALL | FLAME TRACER | ARMOUR PIERCING |

| 1/8/1938 to 31/12/1938 | 4 100 340 | ||

| 1/1/1939 to 31/12/1939 | * 17 187 540 | ||

| 1/1/1940 to 31/12/1940 | * 46 430 540 | 1 003 150 | |

| 1/1/1941 to 31/12/1941 | 51 021 100 | 520 000 | 2 239 700 |

| 1/1/1942 to 31/12/1942 | 100 585 160 | 4 091 100 | 2 735 700 |

| 1/1/1943 to 31/12/1943 | 186 591 820 | 6 095 700 | 21 282 300 |

| 1/1/1944 to 31/12/1944 | 239 910 512 | 10 569 832 | 7 078 760 |

| 1/1/1945 to 31/12/1945 | 53 604 385 | 4 018 560 | |

| Total: | 699 431 397 | 25 295 192 | 34 339 610 |

Total number of cartridges produced during the War: 759 066 199 Rounds

* Includes 250 000 and 1 714 700 rounds loaded in 1939 and 1940 respectively with strawboard wads for Air Force use.

The explosion at the Grand Magazine in Pretoria which did significant damage to the loading facility and the end of hostilities, especially in North Africa and the middle East, for which South Africa was the main supplier, contributed to the fall in production in 1945.

different neck crimps used

different neck crimps used

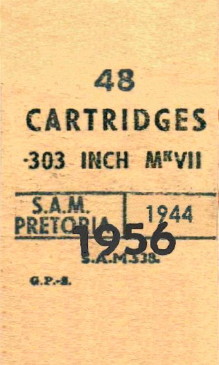

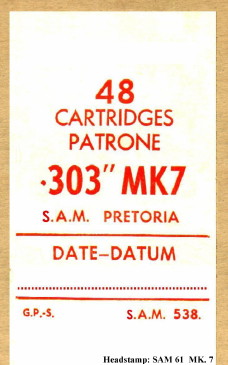

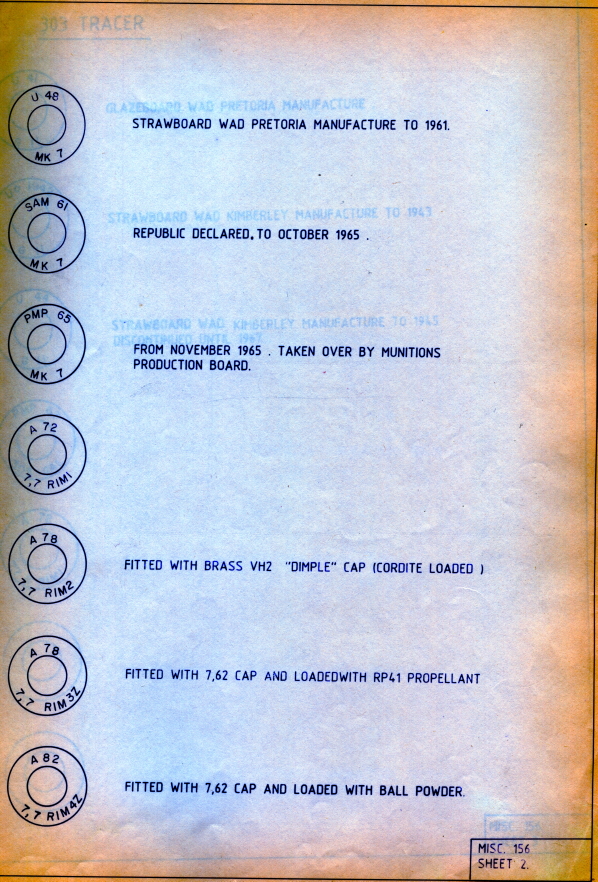

POST WW2 PRODUCTION

It was during this period that the Mark on the case was changed from the Roman numerals in use during the war to Arabic.

It was during this period that the Mark on the case was changed from the Roman numerals in use during the war to Arabic.

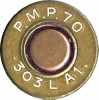

South Africa became an independent Republic on the 31st of May 1961 and, as can also be seen with RSA produced 7.62mm NATO ammunition, the headstamp changed during the latter part of 1961 to SAM (SA Mint). On the 1st of December 1964, the factory was placed under the control of the Armaments Board and its designation changed to Pretoria West Metal Pressings. The SAM headstamp variation remained in use until October 1965, in all probability to use up all existing stock, when the changeover to PMP was done, so there was an overlap period between SAM and PMP headstamps used in 1965. No PMP dated round from 1964 has been observed, either in .303, 9mm P or 7.62 NATO.

broken bunter

broken bunter

Headstamp has distinct punch markings. There are a variety of PMP headstamps, as can be seen above that are with or without period marks or even with only some period marks. As discussed from the specimens in the beginning when testing of the loading equipment was done during the late 1930’s, it might indicate the testing of the durability of the bunter as the headstamp is very shallow and indistinct.

These two specimens with no headstamps were in all probability used during the mid to late 1960’s. The 6mm Musgrave was introduced in South Africa in 1969 with these exact same no-headstamped cases. It would not therefore have made sense for PMP to load these on cases dating from WW2.

Specimen with PMP ·303 style was introduced in 1970. Notice the broad and shallow ‘0’

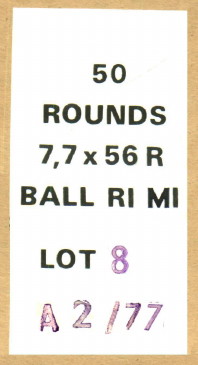

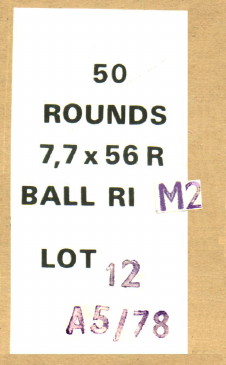

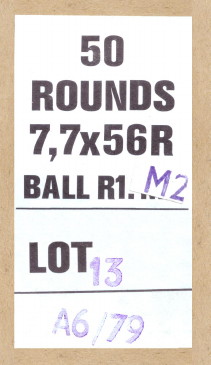

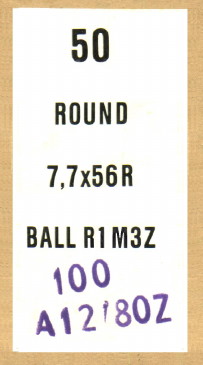

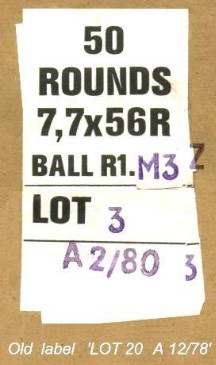

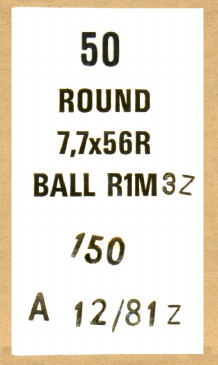

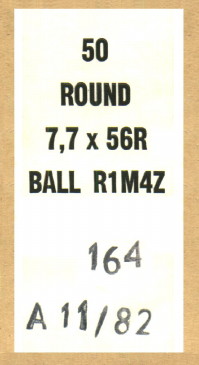

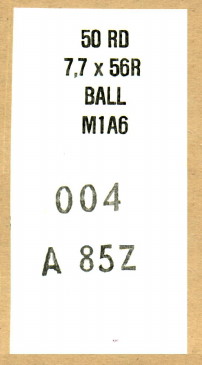

PMP dated headstamps remained in service until the end of 1972. The Armaments Development and Production Corporation (ARMSCOR) was founded in 1968 and the PMP factory was placed under ARMSCOR control and redesignated Pretoria Metal Pressings (Pty) Ltd. 1973 was also the year that the Model Number code was introduced together with a two-digit date. Also introduced was a variation of the British Modelling System (L1A1), where the R1M1 was used. R denoted the Republic of South Africa (RSA) and 1 denoted the first model of the specific calibre. Any change that would affect the operational ability or efficiency would necessitate a change from R1 to R2 etc. M1 is the first mark of the specific model and any concession or deviation from manufacturing specification that was granted to a manufacturer but would not affect the operational efficiency of the design would then change the Mark from M1 to M2 etc.

The last A 78 headstamp is an error as R1M3Z was the 7.62 cap and not the R1M2 dimple cap.

The bullet on the right was a 175gr. boattail experimental used during early 1981/82. Most were without headstamp, although some were loaded in A81 R1M3Z cases denoting the 7.62 NATO cap and RP41 powder.

1983 saw the most significant change in ammunition manufacture in South Africa. This change affected the whole spectrum of ammunition manufacturing, from small arms ammunition up to naval ammunition. Medium, large and Naval ammunition fall outside the scope of this project, but for small arms the changes were that all markings were simplified to a year of manufacture and an abbreviated model number that replaced the old manufacturer monogram, year, caliber, model and code letter that denoted the role of ammunition used. Under the 7,62mm NATO project is a complete discussion regarding all the changes for the post-1983 change. In terms of the .303 project, it is noted that even though the change occurred in 1983, there was no 1983 or 1984 production. The R1M3Z version from 1985 is the only one noted and also marked the discontinuation of .303 military production in South Africa.

SUMMARY OF DESIGNS ON BALL AMMUNITION

Although the above specimens are not South African they are still found in large enough quantities in South Africa and included here for continuity. These were Portuguese manufactured, in all probability during the sanction years. The RNRA was always assumed to be the Rhodesian National Rifle Association, however from correspondence it is known that there never was such an association.

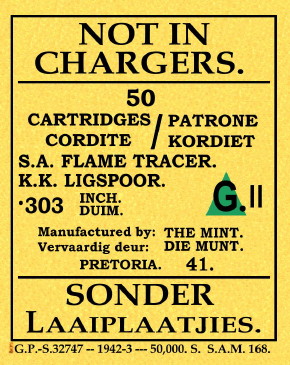

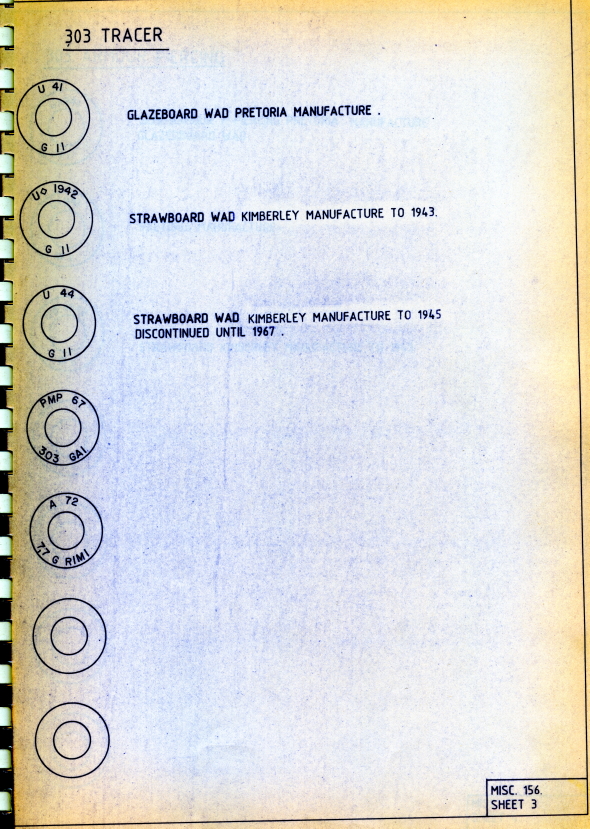

TRACER

Production of .303 tracer in South Africa started in 1941 and continued through to 1945. As with ball ammunition, South Africa again followed the British pattern with a red lacquered primer annulus and the letter G denoting tracer. No tracer ammunition produced in South Africa had a red tip. Some of the first production tracer were secured with a cone crimp, however, because it was used in aircraft, the crimp was changed to a heavy three-segmented mouth crimp.

The H ᗑ N 44 G II (Royal Ordnance Factory, Hirwaun, South Wales) specimen came with a note from the old Peter Skala collection as “assembled in SA”. I have not been able to find any concrete proof of this and why it would have been done. Surely at that stage there was no shortage of tracer as the Kimberley records show that over 10.5 million tracer were manufactured and loaded in South Africa during 1944. One assumption is that there was a greater need for tracer in North Africa or the Middle East, and South Africa was at that stage the main supplier of .303 ammunition to those theatres. Components might have been sent here for assembly, but this is speculation only at this stage.

Production of tracer started again in 1967, and as can be seen in the 1967 production, both the purple and standard red annulus was used, together with G still according to the British pattern but with added A1. South Africa ceased producing .303 tracer ammunition in 1969. One specimen that is interesting is the one with only .303 at the six o’clock position. According to Pamphlet 20, this headstamp was produced from 1946 to 1965, so the timeframe is too wide to ascertain with certainty. My assumption would be that it would be closer to 1965 than 1945. When the War ended in 1945 there was little use to continue production, even going as far as introducing a new headstamp. Closer to start of production in 1967 would be a better guess, but not confirmed, and in all probability in one small lot for testing purposes. No box has ever been examined or confirmed to still exist.

The notes I have state that the specimen with blackened base is a tracer proof round, which seem likely as there are other early proof rounds with blackened bases as well. The red annulus for tracer can be seen as well. No box was available for study.

The notes I have state that the specimen with blackened base is a tracer proof round, which seem likely as there are other early proof rounds with blackened bases as well. The red annulus for tracer can be seen as well. No box was available for study.

The specimen below was part of a lot of tracer ammunition that was manufactured on contract for Rhodesia. These specific cartridges bore the same headstamps as the South African issue tracer of the time; however, these tracer projectiles were marked with a red lacquered tip. There is no record of the quantity of this order. The copper primer is also sealed with lacquered red as per standard RSA practice.

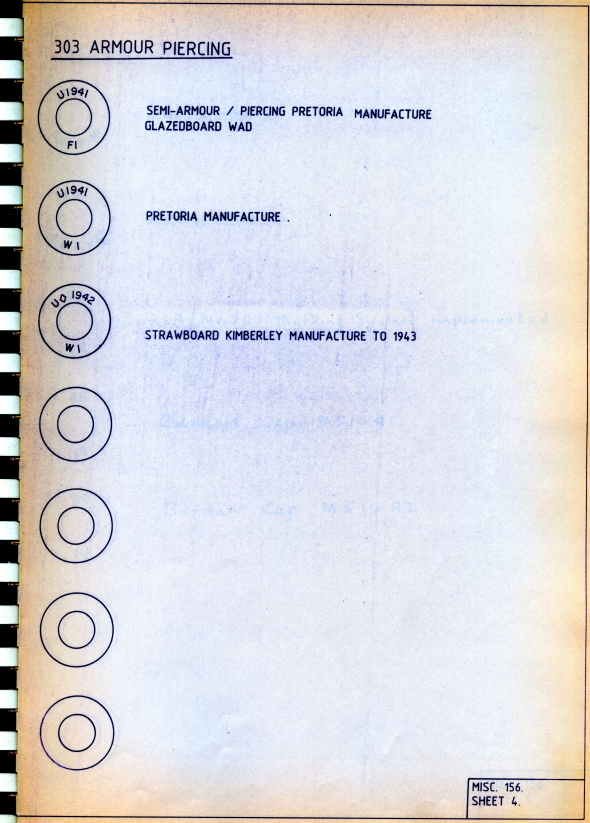

ARMOR PIERCING

The history of armor piercing and semi-armor piercing .303 ammunition in South Africa makes for interesting reading. Armor piercing ammunition was manufactured from the middle to late 1940’s up to 1944 only and in the beginning up to early in 1941 steel procured from ISCOR (Iron and Steel Corporation of South Africa), today known as Arcelor Mittal, was used for the cores, but these were found to be unsuitable, as the desired hardness and consequently, desired penetration could not be achieved. These cartridges therefore had to be classified as semi-armor piercing. According to Mr. D.H Shaw, then manager at PMP, these semi-armor piercing cartridges were developed more by accident than design. Afterwards imported steel was used for the cores. As Britain had her back to the wall at that stage, it is unconfirmed, but probable that the steel used was imported from the USA.

Different neck crimps used on armor piercing ammunition. The short crimp was used in 1940 and early 1941 production. The longer crimp was used on all further production except for one specimen examined with U 1942 W 1 headstamp that have extra-long neck crimps. The specimen without the neck crimp is an unusual round with the U ◊ 1943 W 1 headstamp with brass primer, this could have been some primer material experiment. Copper was a strategic material during the war and brass (an alloy of copper and zinc) would have meant a saving in copper. However, the larger the zinc content, the harder the brass which might have caused problems with the firing pins on aircraft to being able to detonate the caps, so this might have been some short-lived experiment, but this is mere speculation at this point without any evidence. The box is unmarked, headstamp is U ◊ 1944 W 1.

A very early armor piercing round has been reported as having the standard Mark 7 (U 40 VII) headstamp, but with correct green primer annulus as is standard on armor piercing ammunition, but this specimen has not been available for this study.

The first correctly headstamped armor piercing .303 produced in South Africa had the U 40 VII P headstamp. This is an interesting headstamp as the P designation for armor piercing cartridges were the old 1916 designation that sometimes employed a two-diameter steel core within a cupro-nickel jacket, there is also a reference (British Ordinance Board Proceedings) that states that the ‘P’ core has a larger diameter than the W.I core. This British (P) type of armour piercing cartridge became obsolete at the end of World War 1, so it seems odd that this headstamp was even used. Mention is made in Labbett: p.74 of Mk.7 ball envelopes with hard steel core tips in place of the normal aluminium that was sent to England during 1940 and it was claimed by South Africa that these bullets gave better AP performance than W. Mk.I bullets. To test this, the Ordnance Board had bullets made with tips of 3% tungsten carbide steel. This led to an increase in the bullet weight to 185 grains. Tests were conducted at 100 yards with no impairment in accuracy and, while some improvement over standard Mk. VII ball was noted, there was no improvement over existing Mk. I W armor piercing. Further tests were done during the end of 1940, again with tungsten carbide tips and the ogive changed to 1.4 CRH (Caliber Radius Head), or radius of curvature, but again no improvement was noted. Labbett:74 states that “the Ordinance Board of 1940 were unaware that they were in effect reproducing the .303-inch Ball Mark VII.S of 1915 which had been of similar construction (except that the steel tip was without tungsten carbide) and which at the time had been found ineffective.”

During May 1941 there were again reports of armor piercing bullets that were superior to the standard British W Mk. 1 and that this bullet was provisionally designated ‘Cartridge SA Semi Armour Piercing .303-inch F Mark I,’ apparently unaware that a cartridge with the nomenclature ‘Mark VII.F’ approved in 1916 already filled this F Mark I slot. (Labbett:74). The report mentioned that “the bullet weighed 168 grains, including a 90-grain core, and the bullet, with a charge of 36 grains of cordite, had a muzzle velocity of 2365 feet per second. Quantities of this cartridge were sent to Britain for Ordinance Board trials, at which point it was found the bullet diameter was only 7.85mm (.309”) and engraved satisfactorily only in new cold barrels, not in old or worn ones. In new and cold barrels, accuracy and AP performance were both satisfactory at 100 yards range but fell off sharply at longer ranges. The ‘F Mark I’ was not judged fit for service and late in 1941, the Union of South Africa decided, in the light of the Ordinance Board findings, to shelve their bullet design. In the United Kingdom it was, for record purposes only, retitled as ‘Cartridge SA Armour Piercing .303-inch W Mark II’, after which it passed into oblivion.”

There are two known headstamps for this cartridge, namely U 41 F1 and U 1941 F1. As with the P designation on the earlier .303 version, it is still a bit of a mystery why these two different headstamps were used. The U 1941 F 1 was certainly meant for aircraft use as the full date signified the strawboard wad as opposed to the glazed-board wad on the U 41 F 1 headstamp. John Munnery, in conversations with Arno Klee from the RSA Cartridge Collectors Association noted the time it would have taken for these cartridges to be sent to England, tested and the results sent back to South Africa. The factory could not sit idly and wait for the test results as daily production was crucial at that stage for the War effort. By the time the test results were reported from the Ordnance Board, a large number could have been completed and assembled using existing ISCOR steel cores. The cost and effort involved in the production of alloyed steel cores would have been an expensive undertaking and these cores or assembled bullets would not just have been discarded, much less loaded into standard Mk 7 ball cases. Instead, these were designated as semi-armor piercing and given the ‘F 1’ designation. There are no records what these semi-armor piercing were used for, as from that date of the test results from the Ordnance Board, all further armor piercing tests were suspended and South Africa adopted the British W 1 bullet. South African semi-armor piercing cartridges are relatively rare today.

Below is a summary from the British Ordnance Board Proceedings from John Munnery in conversations with Arno Klee in 1983.

1940

8727 South African AP. 165gr projectile is constructed with a longer steel core than British W1, the GM (gilding metal) envelope is thicker than the British W1 envelope. The velocity is 2490 fps with the same charge as the standard Mk. VII ball cartridge. The cartridge has an air space in the nose.

9563 The first South African armor piercing characteristics was found to be inferior to the British WI.

9776 South African semi-armor piercing cartridge is similar in construction to the ball Mk. VII cartridge, the difference is that it has a steel tip in front of the lead core in lieu of the aluminum tip. This only resulted in a slight improvement in penetration over that of the standard ball Mk. VII cartridge. Certain manufacturing difficulties were encountered so Britain decided not to continue with development with this style of projectile.

1941

12440 One South African (Cartridge SAP .303 F Mk. I) tungsten core projectiles sample is sent to Britain for comparative trials where it is designated as ‘Cartridge SA AP .303 W Mk.II/LA/’

13969 (Previously 8827) South African tungsten core armor piercing (F Mk. I)

The projectile weighs 168.3gr with a cordite charge of 36gr. The initial muzzle velocity is higher than that of the British W.I. The penetration capabilities at 100 yards were also greater than that of the British WI. Its performance was superior to the British WI in new barrels but markedly inferior in worn barrels. The conclusion was that it would be satisfactory in emergency use only.

14274 South African Straker (invented by Mr. Stryker) armor piercing cartridge is effectively like the British WI. However, only part of the core is hardened. This would affect a saving in steel – a point in its favor. A clip of five was forwarded to the British authorities for testing. Previously tested in 1938/9, the results were documented in OC memo 1468 and Ordinance Board Proceedings 1633 and 3829.

14742 The South African semi-armor piercing (F Mk. I) is unsuitable for N.S. (the meaning of NS is unknown)

15107 South Africa discontinues development of the semi-armor piercing (F Mk. I) cartridge because of the findings of the Ordinance Board (OB) trials. Therefore, the investigation is removed from future OB trials.

15360 South Africa reverts to the British W.I armor piercing design.

The first specimen is a spotter type round with yellow/red markings. The bullet is strongly magnetic, and the tip has been bored out and sealed with some type of substance after the paint was applied. There is mention in Labbett:143 of …“The Straker Explosive Bullet originated early in the 1939-45 war in South Africa. This was known as the Straker bullet which was duly tried at Simonstown. Later, in August 1941, a small quantity of this ammunition was sent to Britain for trial and was then tested by the Ordnance Board. The trials were not very encouraging and were halted at an early stage. The bullet was intended mainly for anti-aircraft work and consisted of a Mark 7 ball bullet with the nose bored out to receive an explosive cap, inserted 5mm (.19″) into the bullet. Upon impact, this explosive cap was crushed against an anvil and exploded a further charge apparently held in the nose portion of the bullet. Further details of this design are lacking.”

The second specimen is some type of plate test cartridge, but the exact nature of the project in unclear. The headstamp style is from the mid 1980’s, a period where the 303 British was phased out for military use.

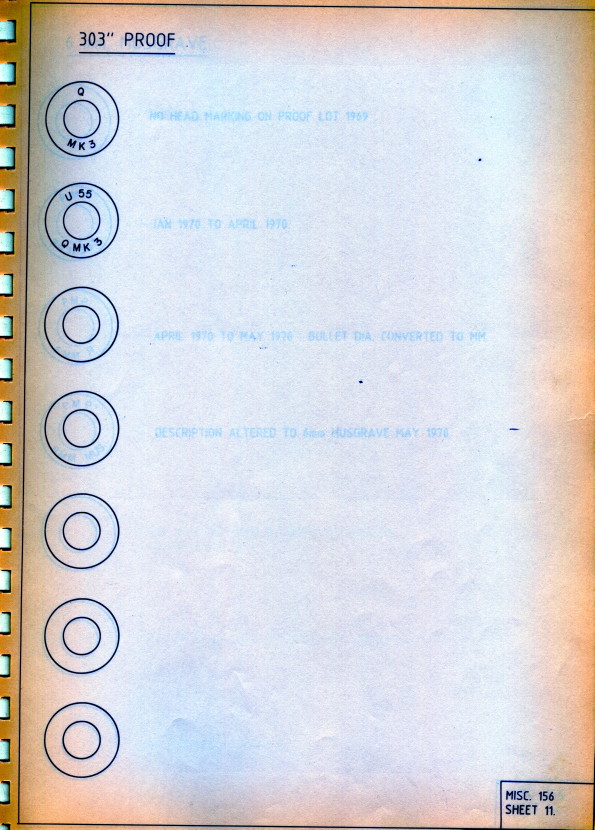

PROOF

The first known proof cartridge is loaded on a U 41 VII dull nickel plated ball case. The nickel plated GMCS projectile is secured into the neck with three long typical neck stabs, the plated primer is ring crimped into the case and is sealed with a purple PA; identical to that used on the standard ball load. As far as we know, this is the only type of proof round that was used in South Africa during the War years. There is no record however of how many were manufactured. During the post WW2 years, only two batches of proof cartridges were manufactured, with one having a U 55 Q . MK . 3 headstamp and the other one was an undated round. South Africa followed on from the British system denoting Q as proof ammunition.

Other proof loads were made up by the Mint, we assume as and when needed. These proof cartridges were all loaded on standard ball cases with purple PA’s and have honey-colored tips. The honey-colored lacquer covers almost the entire projectiles and on some the entire projectile is covered to the point where the lacquer ran down the case side.

As with the 7.62 NATO, others had a black or honey coloured lacquer/paint applied to the base and/or projectile tip or perhaps any combination thereof, the most common being honey tip.

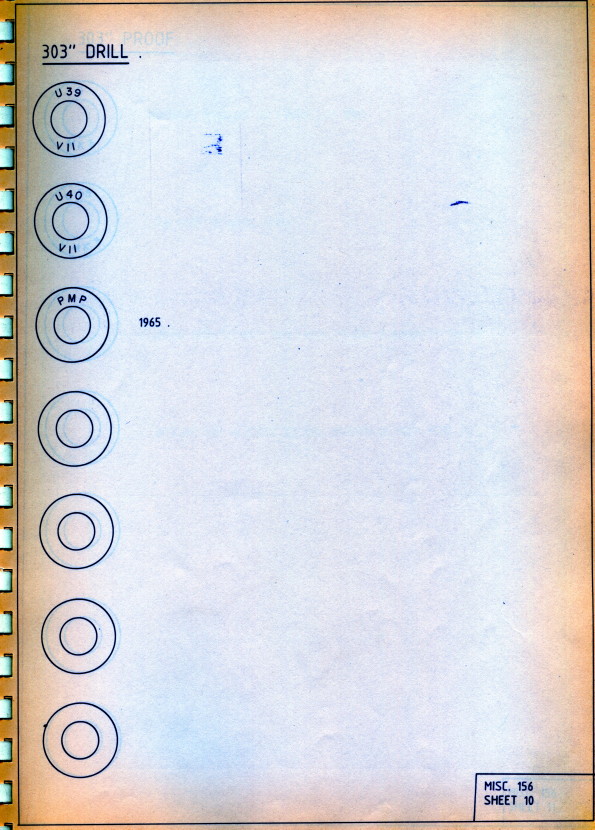

DUMMY AND DRILL ROUNDS

Drill and dummy cartridges were ever only produced on a small scale in South Africa during the War years and usually because of some operational requirement or special order. South Africa has never manufactured any dedicated drill pattern that was marked as such according to the British system, and whatever cases were available as rejects or surplus was usually used. Drill rounds had a standard two holes drilled at right angles in the case, where dummy rounds were plated and fluted. The first dated drill rounds were from 1939 and were assembled with a wood rod spacer on a standard GMCS bullet. The rounds are nickel plated and fluted, some with the flute marked in red, except for one unfluted specimen. Specimens without headstamp exist and these may have been very early manufacture and all the ones examined were not nickel plated, but standard brass cases. The bottom right hand specimen without headstamp has a red wood spacer and CN bullet, neither of which were used by the Mint, either before or after the relocation to Kimberley. It is assumed that these were supplied by the British as calibration examples.

The U 40 VII round employs a wood rod spacer; is nickel plated and has (originally) unpainted flutes. As with the U 39 VII specimens above, these rounds are always without primers and always have three short bullet securing neck stabs. The first U 41 VII round was also loaded with a wood rod spacer; it is un-plated and without flutes. The GMCS bullet is secured with three neck stab crimps and the empty primer pocket is ring crimped. The second specimen has been chrome plated with the original primer drilled and threaded. This was in all probability for some sort of display and not a standard drill round. This might also have been done at a later stage and not during the War years.

The U ◊ 1943 VII dummy is a non-standard pattern dummy with a pair of large drilled holes and is loaded with a GM projectile secured with three long neck stabs and has a fired copper primer with ring crimp. Since the strawboard wad is visible within the case, it is obvious this was once a loaded round that was drilled, and the cordite removed through the holes. These 1945 drill rounds were fitted with wooden bullets instead of the standard GM ones and it might have been to produce a cheaper alternative as both have seen extensive service.

The specimen above is a reworked dummy from Holland. The bullet has been soldered in and two grooves have been added. The date of manufacture is not known.

POST WAR PRODUCTION

The U 56 MK . 7 round was loaded with a GM steel core, without cannelure. To the best of our knowledge this style of projectile was never manufactured in South Africa. The entire cartridge, without the projectile having been removed, is electroplated with a matt silver colored finish. Although, still unconfirmed at this stage, it is suspected to be plated with silver, possibly making it some sort of presentation/decorative display dummy. The steel cored GM jacket projectile is without any crimp securing cannelure typical of all but one, boattail match projectile, RSA manufactured .303” projectiles.

The exact use of the above specimen is unclear. At some stage most of the case was covered by a white paint. There are unconfirmed reports that this was a Rhodesian project, but there is no corroborating proof. The white painted dummies were also used in the old days by Lyttleton Engineering Works and there are documented specimens under the 7.62 NATO section, but again there is no evidence to support the theory that it was also applied to .303 ammunition.

Early dummy rounds. The first version without headstamp was used in the period from 1953 up to 1964 while the second with U (Union of South Africa) was in use from 1949 up to South africa becoming a Republic in 1961.

During the 1970’s, drill rounds were made up as required by the military but did not follow any specific pattern. These rounds were made with 2 holes drilled in the case at ninety-degree angles and as can be found with or without wood distance piece and some with an inert primer cap.

These drill rounds with red base were made up in .303 and .380 Mk. 2 Revolver during the 1976 uprising and was issued to reserve units. The chromed and fluted version is the most common encountered.

The A78 version seems at this stage to have been the last drill round to have been manufactured to be used as such and it would seem that after this date these dummy cartridges were probably used for display or presentation purposes only. The dull nickel-plated version above was not an official drill round but was manufactured by a local collector and is shown here for record purposes only. A chromed case version from 1979 is known and for the post 1983 series a dummy was made up from the standard R1M3 case that was polished and lacquered and issued with an empty primer pocket. As can also be seen below, later versions were made for use and display for the civilian market.

Red anodized dummy by a company called Thor Engineering. They made these dummies in a variety of modern calibers.

Red anodized dummy by a company called Thor Engineering. They made these dummies in a variety of modern calibers.

BLANK

In 1894 a cordite loaded rose-crimped case blank was approved for British service as the “CARTRIDGE SA BLANK .303 INCH CORDITE WITHOUT BULLET MARK V” and remained the standard blank well after the end of the War, despite efforts to produce an extended neck blank. South Africa followed the same pattern design and, by examining different headstamp styles used during the War – with/without primer crimp, purple primer annulus or even the use of tracer (G) – the Mint used whatever cases were available, whether new, reject or surplus manufacture. The original charge was cordite, but nitrocellulose was also approved before the outbreak of WW2.

The first known South African blank was on a case dating from 1940 (U 40 VII) which was a standard ball case, and all WW2 production was on ball cases except for one occasion where a tracer case was used (U ◊ 1943 G II). The Mint also followed Britain and other Commonwealth countries who used the British system regarding blank manufacture by not using any mark or model designation on the headstamp.

One notable difference is the difference in the crimp on later SA Mint manufactured blanks. The specimen on the left is the early U 40 VII headstamp and may have been done according to British refence loads supplied during the early part of the War. All subsequent blanks have the slightly lower shoulder but as can be seen from the two specimens on the right, both of which were manufactured in 1943, there were differences in the neck crimps. Specimens with U 45 VII ball cases are encountered, and these were confirmed by Mr. DH Shaw, previous plant manager at the Kimberly Mint that these were for the most part post-war manufacture as the Mint at that stage still had huge numbers of 1945 dated cases left and blanks were manufactured from these surplus cases for several years. According to the Mint records, blanks were never in great demand and apart from surplus 1945 cases, the only other manufacture was done on cases dated 1947 (U 1947 MK 7). No cases after this date are known. There are various blanks that have no headstamps and from records we know that these cases were in use from around 1953 until the mid-1970’s. These can be found with of without primer crimps as well as with clear and standard purple laquer.

During the mid-1960’s the designation Mk. 5 Z was added to the headstamps on PMP manufactured blanks. As can be seen, these are found in a variety of different variations and the PMP and date at the top are found with or without period marks which would indicate either older, worn or broken bunters being used.

Notwithstanding PMP having headstamp bunters for blank manufacture, we still find specimens as shown below where existing ball headstamps were uses. As stated under the discussion on tracer ammunition, PMP ceased producing tracer in 1969, so these were in all probability surplus cases left after the production run ended.

Only two headstamps from the 1970’s have been observed, both dating from 1975. The first specimen was a standard ball case, whereas the second specimen had the dedicated ‘L’ denoting blank added.

There existed ‘independent homelands’ in South Africa from the late 1970’s onward that were areas where specific groups of people (Transkei, Ciskei, Venda, Bophuthatswana) had an allocated area, much like a federalist system, as part of the then SA Government stance on self-determination. At the end of the apartheid era in 1994, all these homelands were dissolved and incorporated back into South Africa. These blanks were reportedly manufactured for these homelands during the late 1970’s to early 1980’s. Constructed on a sporting headstamped case the rose crimp is sealed with red paint. The case is primed with the smaller 7.62×51 brass primer i.e. the M4 primer cap, which is secured with a three-stab crimp.

Often encountered, this is a ballistic blank that was used as insert in a modified 12-gauge cartridge for launching tear gas grenades. Pending confirmation, it might also have been used in the Republic Arms-modified Musler shotgun, similar to the 7,62 NATO version discussed HERE. Only 1991 and 92 dates have been observed.

SMOKE/MOVIE BLANKS

The specimens below are all movie/smoke blanks and can be found with a variety of different headstamps

The specimens beelow are included in this study although they are Rhodesian reworked blanks made from surplus WW2 ball cases during the 1970’s. They were handmade and are found in a variety of different mouth crimps.

____

WOODEN BULLET BLANKS

The Mk.5 blank was authorized for use in rifles and machine guns, although in the latter role it was far from ideal, and the drawbacks of the short-crimped blank had been well noted since the 1920’s when the Royal Air Force initiated a requirement for a .303” blank for use in aircraft armed with Vickers guns. As these Mk.5 rose-crimped blanks jammed easily in the belt-fed Vickers guns, the search continued therefore for some acceptable bulleted or extended neck design. R.A.F trial were held in 1924 with hollow bulleted wooden blanks which performed well in both Vickers and Lewis guns, and apart from considerable muzzle flash, safety screens that were placed eight feet from the muzzle were pierced, raining safety concerns and the trials were halted.

Labbett:174 states that during this period and later Kynoch produced wooden bulleted blanks for various customers, one being the South African Government who purchased these blanks during 1933 for use in the Lewis Guns of the Transvaal Scottish, a volunteer reserve regiment. The K32 specimen below is in all probability from that order and are still from time to time encountered in RSA collections. The right-hand specimen (U ◊ 1943 * VII) is not technically South African but a Danish reworked blank and included here for continuity. It is uncertain when this was done, and the fired cases were reloaded with an unstained natural wooden bullet and reloaded with a brass primer. The original 5.5mm long neck crimp still be seen.

Wooden Bullet (200% scale)

Wooden Bullet (200% scale)

The first wooden bulleted blanks encountered in South Africa was on 1945 cases and can be found with plain or purple primer annulus, suggesting that whatever cases were available were used. These were also unstained, the same as the British pattern.

Records show that the U ·303 headstamp was used between 1953 and 1964. Again, these are found with clear or purple primer annulus, suggesting again that whatever cases were available were uses. For the most part the bullets are unstained although two specimens were examined, one with a reddish colour and the other one with a dark blue bullet.

After South Africa becoming a Republic in 1961, only two dates have been examined produced the SA Mint

With the SA Mint placed under control of the Armaments Board in 1972, the only production dates in this period were two batches specifically loaded in 1967 and 1968 and one batch in 1970. Note that the Mark number has been omitted on the 1967 and 1968 dates. The 1970 specimen has the L designation for blank loading added. No wooden blanks after this date have been observed or reported.

GRENADE BLANKS

According to available sources, there are no indications that South Africa ever manufactured any grenade blanks, this was also confirmed by Mr. D.H Shaw, previous manager at PMP. There are two grenade blanks however that have turned up that would contradict this. The first is an un-headstamped specimen with purple shellacked wad seated in the case mouth and with typical purple seal roughly halfway from the case mouth. At this stage however it has not been 100% confirmed that this specimen was manufactured in South Africa. It was originally in the Arno Klee collection. The second specimen is interesting as it has the U 41 VII headstamp. It has a deep-seated inverted cardboard cup coated in shellac within the neck of the cartridge. The mouth is sealed with a purple lacquer that extends partially down the outside of the neck only and not halfway down the case body like the other specimen.

POLICE/TRAINING/SUBSONIC CARTRIDGES

These police loads are found on standard issue ball cases and are also found on South African 7,62 NATO rounds. The exact nature of these rounds has not been determined but the 7,62 NATO rounds are regarded as sub-sonic loadings. This would seem a fair enough assumption on a NATO round but would not make sense on a World War 2 relic. One suggestion was that it was for range use, being cheaper than conventional jacketed projectiles. The bullets are cast lead, weight unknown, there are not enough known to pull the bullets. The lower specimen has always been accepted as a police load although never confirmed as such.

PRIMER SENSITIVITY TEST

These specimens were found by Mr. L.D. Nell in 2002 during a visit to the Modderfontein Dynamite Museum, while researching the manufacture of ammunition at Modderfontein during the 2nd Anglo Boer War. Among other diverse items in the museum, there was a clip with 5 cartridge cases resembling the igniter cartridge for the 140mm (5.5 inch) G2 artillery canon, being a 303 case with un-necked cases and tapering from the base to the case neck. The cases examined were all the same with the ‘U 45 VII’ headstamp, and from correspondence with ex-employees these were confirmed to having been used in primer sensitivity tests. From a dumpsite on the premises other cases were also recovered as can be seen below with some damaged by fire. Old cases were burnt after testing to ensure no live primers survived. The method used for testing primer sensitivity was based on the Bruceton Test. In this case a steel ball/device was dropped on the primer from a predetermined height. If the primer ignites, the device is lowered by one notch, subject to the parameters of the test. From one specimen below it can be seen where there is a partial indent on the primer, but not hard enough to fire. The tests were then repeated to find the correct sensitivity for the function of the primer as required.

CANON PERCUSSION TUBES

Although manufactured from 303 cases, these percussion tubes are not the focus of this project. Info will be added at a later stage.

untrimmed case

untrimmed case

empty case showing the internal structure with three flash holes and strengthened base.

empty case showing the internal structure with three flash holes and strengthened base.

Headstamp error

Headstamp error

OTHER SPECIMENS

The first specimen is a reworked loading from China, but it is unclear when this was done. The case mouth and the primer were sealed with lacquer indicating that these cartridges could be stored for longer periods. The second specimen is an experimental short range Teflon type bullet. There was a similar specimen in .50 BMG done as well. The third specimen was reportedly manufactured by the CSIR (Council for Scientific and Industrial Research) sometime during the 1980’s. It is a type of short-range load, but the exact nature is unclear.