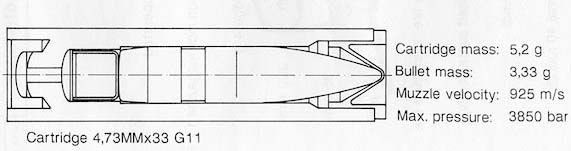

Heckler & Koch development from around 1984 for the G11 assault rifle. The following is an extract from an article The Advanced Combat Rifle Programme (ACR) by J. Lenaerts (B), Military Technology, Vol.XIII, Issue 10.1989.

The projectile is embedded in the solid propellant block, being kept in place and centered by a glued plastic cowl whose inner section holds the projectile tip. The projectile seating is machined into the Propergol block. The projectile base is extended by a copper cap containing a lead styphnate composite which acts as a booster. The cap’s open face is to the rear, towards the igniter which triggers the booster and the Propergol. This arrangement enables the booster to act as a tiny rocket motor, propelling the projectile into the groove cone and, thus, sealing the forward part of the chamber and preventing any gas escaping from the chamber into the barrel. Only this complex arrangement would provide perfectly regular ballistic behaviour with a caseless round. The combustible ignitor is made from the same nitramine-based Propergol compound as the main propellant charge. Its surface contains fine glass particles that serve to ignite the cap once it comes in contact with the rotating firing pin.

The body of the projectile is extruded from a solvent-lubricated material and then press-moulded. Thermal treatment evaporates the residual solvent and hardens the projectile body at the same time. The projectile body is then machine finished. After assembly, the ammunition is subject to various surface treatments to render it water- and heat-resistant and to reduce the effects of friction. On firing, the copper residue and the plastic cowl are ejected through the muzzle.In terms of sensitivity (both during storage and when loaded), the caseless ammunition had advantages over conventional ammunition. It will not burst when hit by a direct impact, nor will it produce splinters; combustion, if any, will be slow and at atmospheric pressure. Moreover, combustion can only be initiated if the igniter suffers a direct hit from a bullet. The cook-off problems were solved long ago, through the use of a propergol propellant that is much more resistant to heat than nitro-cellulose based powders.

Dummy

Dummy

All specimens below shown at 200% scale

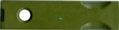

This is a dummy load with green plastic case

This is a dummy load with green plastic case

CNCS bullet with white top cover

CNCS bullet with white top cover

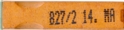

Dummy load with dark green cover. Text on case: 827/2 14.MA // LOS DAG-90-827

Dummy load with dark green cover. Text on case: 827/2 14.MA // LOS DAG-90-827

This might be an early version. GMCS bullet

This might be an early version. GMCS bullet

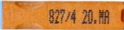

Short range with blue top cover. Text on case: 827/4 20.MA // 4,73 DM18 // LOS-DAG-90-827

Short range with blue top cover. Text on case: 827/4 20.MA // 4,73 DM18 // LOS-DAG-90-827

Dummy load with grey top cover, plastic case

Dummy load with grey top cover, plastic case

Dummy load with opaque top cover, brown plastic body

Dummy load with opaque top cover, brown plastic body

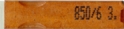

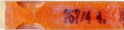

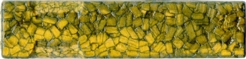

CNCS bullet with reddish/orange case body. Text on case: 767/4 4. // LOT DAG-89-767

CNCS bullet with reddish/orange case body. Text on case: 767/4 4. // LOT DAG-89-767

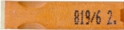

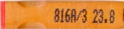

Tracer with red top cover. Text on case: 816A/3 23.8

Tracer with red top cover. Text on case: 816A/3 23.8

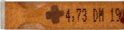

The ‘+’ denotes a PROOF load

The ‘+’ denotes a PROOF load

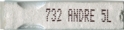

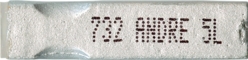

‘ANDRE’ version. Silver coated case for shielding in order to try and compensate for cook-off

‘ANDRE’ version. Silver coated case for shielding in order to try and compensate for cook-off