At the end of the US Civil War in 1865, the military continued in their search to improve the weapons in their arsenal and that lead to the adoption of the Model 1865 Springfield based on the work done by Erskine S. Allin, who was the master armorer at the Springfield Armory in Massachusetts. He was tasked with converting the Army’s muzzle-loading rifles into breech loaders and this resulted in the Model 1865 Springfield in .58cal. During 1866 the design was improved upon and that resulted in the Model 1866 (Allin Conversion) Springfield Rifle in 50-70 cal. The next upgrade happened in 1873 after various trials with the adoption of the 1873 Springfield “Trapdoor” rifle, chambered for the newly adopted 45-70-405 US Government cartridge.

Cartridge production started in January 1874, but according to HWS III, some limited production occurred as early as September 1873. The Benet primed cases were loaded with 70 gr. black powder load and a 405 gr. bullet. The carbine load used the same bullet, but a 55gr. charge with 7 wads inserted to take up the space. The bullets for the carbine load were seated to the same depth as the rifle load and once out of the packet, there was no way to distinguish which was which, until it was fired and apparently the recoil was excessive when a rifle load was fired in a carbine rifle. During July 1874, the carbine loads were given a raised US CARBINE headstamp but the process was quickly abandoned. The rifle/carbine identification problem was solved in March 1877 when the arsenal started applying headstamps to the cases. The first were headstamped R 77 3 F (Rifle / 1877 / 3rd Month / Frankford Arsenal) and C 77 3 F (Carbine). These headstamps are very difficult to obtain.

Benet Primed Carbine and Rifle loads during the pre-March 1877 period. The inside primed cartridges remained the standard until August 1882. The third specimen has the faint US CARBINE headstamp dating from March 1874. From an old IAA forum discussion these rounds were headstamped as carbine as it was at that stage impossible to discern carbine and rifle loads once removed from the packets. These were however in circulation for a very short period, probably no longer than six months from the forum discussions from old collectors. The reason was that the rims were too soft, causing extraction problems.

Headstamps started in March 1877 with the first specimen being from March 1877. Second is a Carbine loading, March 1880. Third is a Rifle loading, December 1881

Model 1882 Carbine load

Model 1882 Carbine load

In January 1882, Frankford Arsenal began experimenting with 500gr. bullets for improved accuracy in the ‘Cal. 45 Rifle Ball Reloading Model 1882’ using reloadable Berdan cases, while continuing to use the 405gr. bullet for the carbine loads. They also experimented with a lengthened case with an additional 10gr. of black powder, the so-called Springfield Sharpshooter, or .45 Lengthened Chamber Rifle. The increased bullet weight and not the increased powder charge was responsible for the improved accuracy, so the lengthened case experiment was dropped and the heavier 500 gr. loading was adopted with the standard 70gr. charge.

The indicating letters R and C were dropped in April/May 1886 because it was then easy to distinguish the rifle and carbine loads. The headstamp also changed to a three positioned, instead of a four position headstamp. Because of the improved powder, the wads were omitted in June of 1886 because the improved powder filled the void that was taken up by the wads. Therefore the model 1886 Carbine loads are seated a little deeper than the Model 1882 loads.

_____

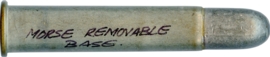

Caliber 45 Rifle Cartridge, Morse Pattern, 1886

The Morse cartridge was produced by Frankford Arsenal on a trial basis Between March of 1886 and February of 1887. The case had a tinned brass case instead of the gilding metal alloy – the so called Bloomfield Gilding Metal used up to that point – to extend case life. The Morse case was made up of three parts, namely a removable base to ease reloading, a rubber seal and a flanged tube (case). It was only trialled for a very short period – until February 1887 – and the assumption is that the supposed benefits did not warrant the additional costs involved in the project. What did survive however were the tinned case and that lead to the Model 1888 cartridge, adopted during October 1888.

During the early part of 1897 testing started on smokeless loads with first production beginning in early 1898. The Model of 1898 was adopted in April 1898 with a 500gr. bullet and knurled case cannelure added. See also Fig 306 p.205 of HWS 1. The adoption in 1892 of the lighter 30 Krag lead to the eventual demise of the 45-70 cartridge and in March 1895 the last Frankford Arsenal loadings for the Army were done, although production continued for Navy and militia use until June of 1898, when Frankford Arsenal ceased all production of the 45 Government cartridge. The specimen below with June 1898 date was the final production date.

CONTRACT LOADS

The R 45 B 70 was by UMC, Bridgeport, CT. R indicates Rifle load and the B indicates Bridgeport. Second Loading was by the United Sates Cartridge Co., Lowell Massachusetts, later style with flat base and external Boxer primer.

Loaded by Winchester for Rifle load in August 1890.

Loaded by Winchester for Rifle load in August 1890.

UMC

UMC

I am still searching for the meaning of the ‘600’ stamped on the bullet.

I am still searching for the meaning of the ‘600’ stamped on the bullet.

BLANK LOADS

Original blank cartridges manufactured by Frankford Arsenal consisted of the copper, inside primed service case 1.6 inch long that was slightly crimped at the mouth and loaded with black powder and kept in place by a paper cup covered by a shellac wad.

During 1879 the Ordnance Office requested Frankford Arsenal to develop a new blank load an in January 1880 experiments were started with various loadings. The specimens below have a small mouth crimp over a paper wad. The bottom specimen was manufactured from a standard service rifle case. Blanks were manufactured from second-class components – fired or reject cases – therefore blank loadings will be found with any period headstamp.

The ‘rifle and carbine blank’ was adopted in the early 1880’s with a case length of approximately 1.85in. These blanks were manufactured from fired cases as well as rejects, so they can be found with or without headstamp and in almost any combination of case type, primer and date on headstamp, even commercial headstamps.

The specimen below was a fired case that was tumbled in sawdust, which removed most if the tinning from the case.

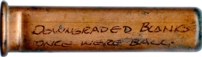

In some cases, the bullets were pulled from defective ball cases and the mouth was crimped over the existing wad already in place.

Military contract blank by Winchester

Military contract blank by Winchester

It was found that the present shaped blanks did not fully function in Gatling Guns a suggestion was made to load the cases with a bullet or similar plug made of wood or paper to simulate a bullet in order to aid feeding in the guns. The bullet were flat nosed to limit their range, but during firing tests, it was found that these wooden bullets still had sufficient force to penetrate about a 1 inch pine board at 30 yards.

In order to overcome the danger with the wood bulleted blank, they experimented with a “whole case blank”, which was closed at the mouth and was 0.3 in. longer than the standard service case but in firing, the cases failed to feed properly. See also HWS3, p. 210 Fig. 316.

One of the last government blank loadings was done during 1903 – 1905 and was also of the whole case type, but with case drawn out and a crimp resembling a ball round.

COMMERCIAL LOADS

Exploder with .22 Rimfire

Exploder with .22 Rimfire

Hornady Leverevolution

Hornady Leverevolution

NPE Case – Georg Roth Austria

NPE Case – Georg Roth Austria

Variations on PETERS loads

Variations on PETERS loads

Variations on REM – UMC loads

Variations on REM – UMC loads

Red wax bullet

Red wax bullet

Vanity headstamp, probably by Starline

Vanity headstamp, probably by Starline

U.M.C Solid Head variations

U.M.C Solid Head variations

First specimen is a Guard (Multi Ball) loading. Experiments with multi ball cartridges started as early as 1878. Second specimen is a load made from commercial ball rounds for gallery practice use and consisted of a 230 gr. lead bullet loaded with 20 gr. of black powder.

LINE THROWING BLANKS

Sharps Line-throwing gun, #C33718, shortened version (Sharp’s Patent April 12th 1859 conversion of New Model 1863 rifle) less than approx. 75 manufactured by Sharps for the U.S. Coast Guard; in good to very good condition; accompanied by afull box (20) opened but complete and unfired, of Western Cartridge Co. ammunition (.45-70 MK I) blank cartridges with box dated 1943 and marked “FOR LINE THROWING GUN”. (Antique). Est.: $1,500-$3,000.

icollector.com