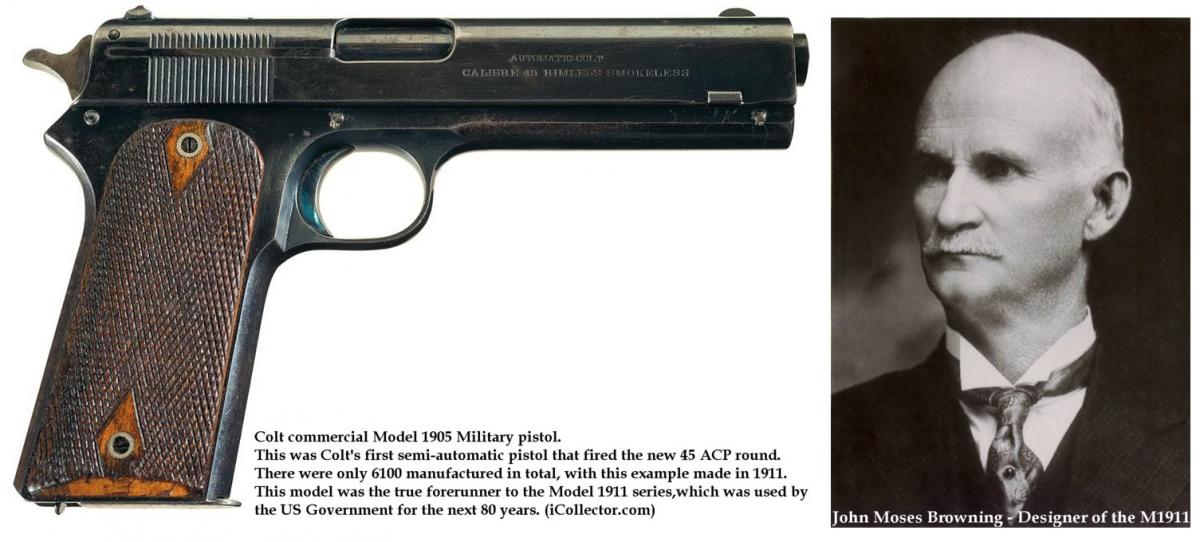

The history of the 45 ACP and the Colt 1911 started during the late 1890’s. At that time there were still a large number of revolvers in use by the US military forces and it was during the Moro Rebellion of 1899 – 1913 in the southern Philippines that the necessity of a self-loading pistol rather than a revolver was realised. US forces still used the 38 cal. service revolver which proved ineffective against the suicide attacks by Moro rebels. It was specified that the new pistol should be chambered in no “less than .45 caliber” and in March 1904 Frankford Arsenal was ordered to start development of a military automatic pistol. Some experimental work was done during 1904 – 1905 with a commercial .45 cal. cartridge by Winchester. Frankford Arsenal received instruction to develop and manufacture a small number of 45 automatic pistol ball cartridges for the 1906 trials. Two cartridges were developed, rimless and semi rimmed version although the semi-rimmed version was withdrawn and only the rimless version was submitted for trials, although it was never adopted. South African versions are listed under the SA Reference Collection on the menu bar above.

.45 Automatic Pistol Ball cartridge “Model of 1906”

.45 Automatic Pistol Ball cartridge “Model of 1906”

Model of 1906 Cal. 45 Revolver Ball

Model of 1906 Cal. 45 Revolver Ball

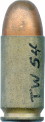

M.1907 thin extractor groove

M.1907 thin extractor groove

Top specimen above from 1907 with narrow extractor groove and no case cannelure from UMC for the Government contract of their commercial design. Second specimen is from the March 1908 change when the width of the extractor groove was increased from 0.085in. to 0.126in. With a few minor alterations this 1908 version became the standardised version that was adopted as the Model 1911. The Colt 1911 was formally adopted by the US Army on March 29, 1911, and then by the US Navy and Marine Corps in 1913.

2nd Amendment Ammunition, Oakmont, PA, USA, cases in all probability made for them by Starline. AACAM is the Argentinian Cartridge Collector Club. This is a commemorative load. A-MERC was by American Ammunition Co., Miami, FL. AMMO INC is by Ammo Incorporated, Scottsdale, AZAMMOLOAD done by Anatolia Cartridge Industry Co., Armutlu-Izmir, Turkey. Distributed in the US by Ammo Load Worldwide Inc., Lewiston, ID. Company is owned by Freedom Munitions. The two THV loads on AGUILA cases might have been NGA loads, but still looking for confirmantion. ACP and AP are by Armscor of the Philippines. ASYM is by Asym Precision Ammunition which is a division of Legacy Custom Products Inc. Durango CO. It is part of a ammunition line of cartridges by Stan Chen Firearms.

Movie blanks manufactured by Gevelot for ARF = Alexandre Regie Film, Paris

BBM SHOT by BBM Corporation, West Springfield, MA, USA. BHA is by Black Hills Ammunition Co, Rapid City SD. The specimens on the right are the new Browning headstamp with deer antler logo

M AER = Ministério da Aeronáutica: Ministry of Aeronautics.

M G = Denotes the cartridge was made for the “Ministerio da Guerra” (Ministry of War).

According to Ken Elks in his book “Chinese Ammunition 1870 to the Present Day” it states that the 20th Arsenal was established in 1938 at Chongqing using premises that used to be an old mint. But it is also stated (page 33) that the presence of a mint at that location has not been substantiated, while the one at Chengdu is a matter of public record. It might therefore have been possible that machinery was brought in from elsewhere and the factory was renamed to Number 20. The symbol on the headstamp resembles a coin with a square in the center. The year 37 equates to 1948 in the Western calendar.

The symbol for Arsenal 90 (Mukden) was a circle with horizontal bar with two small circles above and below the bar. This was done after the Nationalists regained Mukden after the war. 45 ACP ammunition was manufactured at Arsenal 90 in the years 36 (1947) and 37 (1948).

60A = Taiwan Government Arsenal, Kao Hsiung, Taiwan. Year 59 (1970) and 57 (1968)

Heilongjiang North Tool Company, Ltd., Mudanjiang City, Heilongjiang Province, China. (Formerly Arsenal/Factory No. 121)

Heilongjiang North Tool Company, Ltd., Mudanjiang City, Heilongjiang Province, China. (Formerly Arsenal/Factory No. 121)

Hansen Cartridge Co., Southport, CT, used imported cases

Hansen Cartridge Co., Southport, CT, used imported cases

First specimen unknown manufacturer. Second specimen reportedly a Chinese contract load by REMINGTON

DAVE ANDREWS is a commemorative load by CCI for an employee retirement. Cheddite is an Italian Brand from Livorno, but they are more into shotshell manufacturing. The COLT headstamp is by Barnaul, Russia. The COOPER headstamp was done by Olin Corp, for gun writer Jeff Cooper.

The Concord Manufacturing Corporation, of Massapequa, New York, was a successor to Palmer Manufacturing Corporation which evolved from the Dairt Corporation that loaded the Oilite bullets discussed below. They also used surplus military cases that have a yellowish look from the cases being cleaned by some chemical process with a “CONCORD RELOADS” overstrike, this specimen originally having a WCC 42 headstamp. Known boxes of Concord cartridges were loaded in a Palmer box with a light green paste-on label. The company is believed to have been in operation from 1946 – 1950, but the exact dates have not been confirmed.

D I 42 headstamp by Defence Industries, Verdun Canada. DOUBLE TAP Ammunition from Cedar City, UT. The DRT headstamp is by Dynamic Research Technologies, Albany, MO with cases made for them by Starline Brass.

Perhaps one of the holy grails of 45 ACP collecting. Described in “DWM CARTRIDGES 1896-1956” by Datig as the “Autom. Colt-Pistole Kal. 11.43mm (.45″) Amerikan. Armee Mod.” Less than a handful of these cartridges exist in collections today. Apparently one partial box was discovered in Switzerland years ago. This is the excellent article on the Borchard Forums about the history of the .45

The first lot manufactured by the Chrysler Corporation Plant in Evansville Indiana was completed in July 1942 and later it was necessary to add additional facilities at the nearby Sunbeam Plant. The shortage of brass during the latter part of 1942 led to the development and production of steel cases as well as GMCS bullets.

The 45 ACP shot cartridge was requested by the Air Force for use by air combat crews for survival purposes. Original approval was given on the 20th of August 1943 and was called the “Cartridge, Shot, Cal. .45, T23” and during October 1943 this cartridge was standardised as the M12. The paper bullet did not hold up well in humid climates and the design was replaced by an extended brass cased load as well as a elongated case with rose crimp.

EXT SHK is by Extreme Shock USA, Clintwood, VA.

The month designation was dropped from the headstamp on 28th of July 1917. The F A 10 17 headstamp was the last with month/year designation.

Proof Loading

The dummy round was designated the M1921 and consisted of a case with 3 ⅛” holes spaced equally around the case body with an inerted tinned primer. The headstamp style changed in 1934 with serifs omitted

During WW2 there were still a large number of revolvers in service. When the standard M9 blank was used it often resulted in blown out primers, and Frankford Arsenal was requested in early 1944 to develop a blank for use in revolvers. The new blank was essentially a standard M9 blank with a redesigned primer crimp and designated the FAT1E2. During March 1944 this round was officially designated as “CARTRIDGE, BLANK, REVOLVER, Cal. .45, M9”

The critical shortage of brass experienced in 1942 led to the development of steel cases and the last lot of brass cases were done in May 1943. This also lead to GMCS bullets being adopted about the same time.

During 1942 the M1921 dummy round was simplified with a tinned case but without the primer, leaving an empty primer pocket.

The standard high pressure cartridge was the M1 which remain unchanged from the version adopted prior to WW1. It consisted of a standard M1911 bullet and a tinned case for identification.

M1 Tracer rounds were standardised before the war started in 1939. The bullet was GM with red trace and red tip colour with a cross that was stamped on the tip of the bullet which was in all probability done for in-house identification.

In 1941 Frankford Arsenal changed the hardness of the brass used in the manufacture of .45 tracer ammunition to prevent case cracks as a result of swelling of the tracer compound under adverse weather conditions. The cases were made a little softer by annealing and the process was called “high annealing” and a star was added to the headstamp.

FA 56 was the last production at Frankford Arsenal

FA 56 was the last production at Frankford Arsenal

Fabrica de Municiones, Santa Fe, Mexico

Fabrica de Municiones, Santa Fe, Mexico

F.A.M.M.A.P (Fabrica Militar de Municiones para Armas Portátiles)

The Argentine National Executive Power, under the command of General Agustín Justo approved plans on the 27th of September1933 for an Infantry Ammunition Factory at San Lorenzo Arsenal. The necessary machinery and equipment was purchased from the German company Fritz Werner and the works were completed in December 1935 and inaugurated under the direction of Lieutenant Colonel Rodolfo Jackeln. On the 24th of December 1936 it ceased to be an annex to the arsenal and incorporated under the Directorate of Military Factories of the Argentine Army. In 1937 the name was changed to the Military Ammunition Factory for Infantry Weapons. In 1950, the name was changed again to that of Fabrica Militar de Cartuchos ‘San Lorenzo’

F.M.M.A.P ‘B’ (Fabrica Militar de Municiones para Armas Portátiles de Puerto Borghi)

Tracer

Tracer

F.M.C ‘S.L’ (Fabrica Militar de Cartuchos San Lorenzo)

The F.M.M.A.P ‘B’ factory (Fabrica Militar de Municiones para Armas Portátiles de Puerto Borghi) was renamed during 1950 to the Military Ammunition Factory ‘San Lorenzo’. On the 1st of April 1951 the FMC ‘SL’ and the Military Artillery Ammunition Factory were merged under the command of Lieutenant Colonel José Blanco and the name changed to Military Factory, San Lorenzo.

F.M F.L.B (Military Factory Fray Luís Beltrán)

On April 21, 1961, F.M ‘S.L’ (San Lorenzo Military Factory) changed its name to what is known today as Fabrica Militar Fray Luis Beltran. Together with military ammunition, it also manufactures ammunition for the civilian market.

F&S headstamp is by IGMAN and manufactured as the “Field & Stream” brand for Dicks sporting Goods.

Second GECO specimen has the rim flattened to increase diameter. Might be to fit in revolvers? Third GECO specimen is a proof loading.

H&F is for Hardy Et Fils SA, Brussels, Belgium, cases made for them by Starline. Hornady headstamps with dots made by S&B

Hirtenberger Patronen – Zundhutchen-und Metallwarenfabrik, Hirtenberg, Austria.

HPR is for High Precision Range, Payson, AZ, USA, company owned by Advanced Tactical Armament Concepts, LLC (ATAC)

HRTRS is owned by Cabela’s, Sidney, NE, USA, now owned by Bass Pro Shops. These cases made for them by S&B

HXP is for Greek Powder & Cartridge Co., Athens, Greece. (Pyrkal). Now called EAS SA., Attica, Greece aka Hellenic Defence Systems S.A. (EBO-PYRKAL). HOWITZER was a UK brand with cases made for them by Starline

*I* is for Independence Brand. Owned by ATK, although the atk.com website will take you to Northrop Grumman. IMPACT is for 3-D Ammunition Co., Doniphan, NE, now owned by Hornady

The story behind this IVI 45 ACP round is very interesting. The bullet is a copper-polymer composite frangible design by Longbow Incorporated of Burns Flat, OK. The design dates from the 90’s and was made in 9mm, 5.56 and .45. They originally manufactured and sold their own ammunition to military, police and certain civilian agencies. IVI did not manufacture 45 ACP ammunition, but a Canadian collector found an old photo of a 45 ACP case with IVI headstamp. During 2001 an order was placed with IVI for a single batch of reportedly 10,000 rounds of training ammunition loaded with the Greenshield® copper-polymer frangible projectile, in .45 ACP calibre. The order was reportedly by or via Simunition, who at that stage held the Greenshield patent. This single lot was apparently all shot and the brass recycled. All subsequent orders were on cases manufactured by Winchester. By some luck, the Canadian collector managed through some minor miracle to find one box of fifty rounds of the original loads. See also IAA Journal 555, Jan/Feb 2024.

J – A O is for Asahi-Okuma Arms Co, Japan. Next is a proprietary headstamp for friend and fellow collector John Moss

KEN BOREL is a commemorative load by CCI for an employee retirement. The LE headstamp was for Leader Trading GmbH, Ratingen, Germany and originally produced by Giulio Fiocchi, Lecco, Italy.

Maxim Munitions Corp. WW1 contract loads

Maxim Munitions Corp. WW1 contract loads

Small Arms Ammunition Factory N°1, Footscray Australia

Small Arms Ammunition Factory N°1, Footscray Australia

Small Arms Ammunition Factory N°2; Footscray Australia. The G denoted Gordon Street, Footscray.

Small Arms Ammunition Factory N°2; Footscray Australia. The G denoted Gordon Street, Footscray.

National Cartridge Co., Atlanta, GA, Cases were made by Olin Industries and loaded by Hornady (Frontier) in the 1980’s. NEVINS headstamp by Nevins Ammunition Inc., Boise, ID, Cases manufactured for them mainly by Starline. NSI is for Nobel Sport International

Ordnance Factory Nigeria. 7,62 NATO case

Ordnance Factory Nigeria. 7,62 NATO case

P-A is Precision Ammunition LLC, Tampa, FL. P.C Co is Peters Cartridge Company, 1st WW contract load.

Pro-Load Ammunition, Post Falls, ID

PPU Yugoslavia

PPU Yugoslavia

Above specimens by Raufoss Norway. First specimen is a model m/28 with early nickel plated brass and was made between 1928 and 1946. 2nd and 3rd specimens are post-war m/28 with GM bullet.

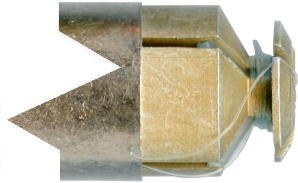

Oilite Bullet

Oilite Bullet

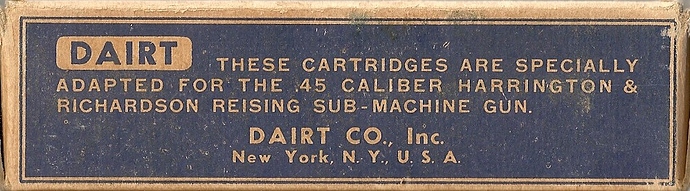

Oilite Bullets were made by Amplex Oilite Products Co. which was part of the Evansville Chrysler Corporation. It was loaded by the Dairt Company, Inc (New York, N.Y.) which was one of at least three companies on New York’s Long Island that reloaded fired .45 ACP cartridge military cases during the early years of World War II. The cases all have a distinct yellowish color when the original fired cases were cleaned. The cartridges were loaded with a pressed metal bullet of a copper composition referred to as Oilite instead of sheet copper; the powdered metal contained some form of lubrication, with the intended purpose of reducing barrel wear, but tests done by the Military did not show evidence that supported that. Dairt also manufactured some experimental .30 caliber bullets for Frankford Arsenal in 1941.

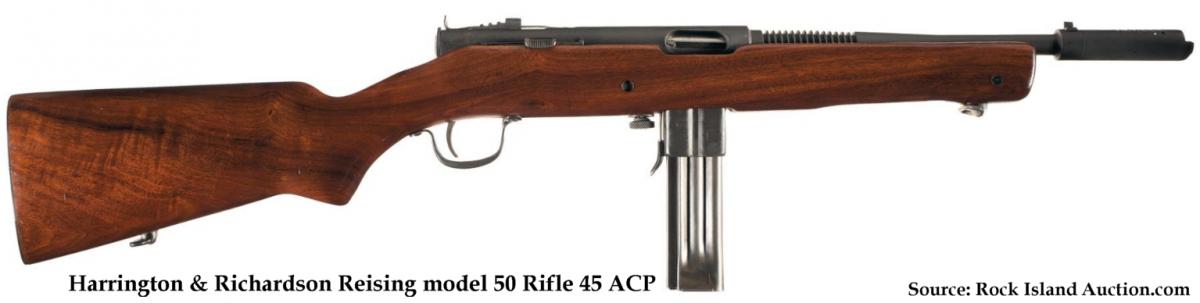

On the Dairt boxes mention is made that the cartridges are adapted for the Harrington & Richardson Reising machine gun. The Reising Model 50 Submachine Gun was developed by Eugene Reising, and manufactured by Harrington and Richardson Arms Company in Worchester, Massachusetts. Because of issues by the Marine Corps in obtaining the Thompson Sub-Machine Gun, they adopted the Reising, which was an early attempt to supply US troops with a small and portable 45 ACP sub-machine gun but there were many issues regarding the reliability of the gun. The grit and grime of the Pacific caused many problems as parts were not always 100% interchangeable as they were made to much tighter tolerances at the factory. Many mechanical failures were experienced when parts got mixed up during cleaning and re-assembled in different guns. This led to instances where the guns were ditched, apparently in rivers and swamps by the soldiers.

Shot load

Shot load

Chromed Dummy

Chromed Dummy

WW 1 Contract Load

WW 1 Contract Load

First specimen is a riot load.

Unsure about the first specimen, it might be a very early Glaser type but I don’t have specific confirmation yet. The second specimen resembles a French Arcane loading, bullet not magnetic. Last two specimens are Glaser Safety Rounds. The blue tip is a #12 shot and the gray tip is a #6 shot.

The time delay shot cartridge was submitted to Frankford Arsenal in June 1972 by the L.O.M. Corporation as part of the Personal Defensive Weapon (PDW) program but not adopted by them because of the idea of it being too complicated. But in early 1973 L.O.M was given a small development contract for a more simplified design consisting of a four segmented steel sabot filled with lead shot. The front of the sabot was tied with monofilament that would unwind in flight to release the shot. See also HWS 3 p. 33

First specimen is a wooden blank by Raufoss, The second is for Republic of the Philippines Arsenal, Manila. The RUGER headstamp is by Polycase Ammunition, Savannah GA and is loaded with the ARX Inceptor frangible bullet.

SB is the old Squires Bingham, Philippines. The third specimen is what is known as a “Pin Grabber” bullet designed by Bill Kaswer in the 80’s and was a saw-toothed 260 gr. bullet designed to ‘grab’ a pin more effectively than conventional bullets when hit off-centre.

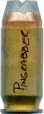

SF = Société Française des Munitions (Gévelot) à Paris (In many cases SF supplied their own cases as well)

I = Société de Métallurgie Franco-Belge à Issy Les Moulineaux.

From and old IAA Forum thread – The loading with the yellow base was from standard French military cartridges converted to subsonic from original components by a company called EXPLORACO Texas.

First specimen without headstamp is the 1st lot manufactured by SFM 1924. Second specimen is an Ethiopian Contract load loaded for them by SFM

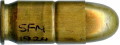

SMI: Societe Metallurgica Italiana, Campo Tizzoro (Italy) and was used on NATO military contracts.

SMI: Societe Metallurgica Italiana, Campo Tizzoro (Italy) and was used on NATO military contracts.

Top Brass is a brand name by Armscor and made in the USA by Scharch Manufacturing, Salida, CO. The TEXAS headstamp is by Texas Ammunition Co., Ballinger, TX, USA. The TRA headstamp was done by Armscor in the Philippines for Transarms Germany.

The majority of .45 Ball ammunition used during the Korean War were from commercial sources. Twin Cities started in 1953 with production by first using steel cases with zinc-chromate finish but when problems arose, converted to brass cases. (Specimen above is a reload).

TZZ is for Israeli Military Industries

The UNDERWOOD headstamp is by Underwood Ammo, Charleston WV. Last three specimens are WW1 contract loads

WW1 Winchester contract loads

WW1 Winchester contract loads

Last specimen is an anodised aluminium case

Last specimen is an anodised aluminium case

The notes I have state that this was made by BOSS from South Africa during the 80’s which used the typical blue primer annulus. – still awaiting confirmation.

The notes I have state that this was made by BOSS from South Africa during the 80’s which used the typical blue primer annulus. – still awaiting confirmation.

Winchester, Division of Olin Industries, Oxford, MS, USA. – WMA means “Winchester Military Ammunition”

Winchester, Division of Olin Industries, Oxford, MS, USA. – WMA means “Winchester Military Ammunition”

2nd and 3rd specimens are some type of Glaser/Magsafe loadings, exact types to be confirmed.

2nd and 3rd specimens are some type of Glaser/Magsafe loadings, exact types to be confirmed.

This bullet resembles a Federal Hydra-Shok bullet, but all lead including the central “pillar”. Second and third specimens have Exploder type bullets, exact description to be confirmed

First specimen is a Segmented bullet experimental by Aberdeen Proving Ground in 1972. Consists of a round nosed lead bullet in six segments and loaded at APG for the Small Arms Systems Agency. The tests proved unsatisfactory and further tests were halted in August 1972. (See also HWS 3 p. 31). Third specimen is a shot loading and might have been part of the March 1962 loadings by Frankford Arsenal on behalf of Ballistic Research Labs. (See also HWS.3 p.29)

Resembles a Glaser round (shot load, pink rubber type seal)

Resembles a Glaser round (shot load, pink rubber type seal)

Zero Ammunition Co., Cullman, AL., USA. – Cases with small font made by Olin Corporation after 1985

Zero Ammunition Co., Cullman, AL., USA. – Cases with small font made by Olin Corporation after 1985

AIMSPORT snapcap (Italy). Second specimen is a dummy cartridge by the German firm H. HUCK. Third specimen is a Sub-Caliber with 4mm ŰBUNGSMUNITION M.20 insert. Fourth specimen is a 22LR sub-caliber

Steel 22LR Sub-Caliber device, second specimen is by Pachmayr, Italy. Third is an aluminium dummy with TRADITIONS 45 ACP on the side.

Unknown. The label just states “Mexicaine 3275”

Unknown. The label just states “Mexicaine 3275”

Short range training cartridge by OZKURSAN, TURKEY. The orange injection molded dummy is by Precision Gun Specialties Inc