South Africa started manufacturing of the 38 Special cartridge in 1969.

This was the first 38 Special headstamp manufactured by PMP and was only used during 1969. In 1970 the headstamp was modified to remove the .380 and only included .38 SP in different variations as seen in the specimens below.

Early manufacturing used Berdan primers

Early manufacturing used Berdan primers

These are the current headstamps and are found in JSP and JHP versions

These are the current headstamps and are found in JSP and JHP versions

Wadcutter

Wadcutter

SWC load

SWC load

Snake shot loads with different shot sizes

Snake shot loads with different shot sizes

Dummy loadings, first specimen is a show dummy, the second specimen has the PMP overstamped by three &&&. The third specimen has a rubber primer insert to also function as a snapcap.

Blank loading only seen on 1969 production. The specimens below are movie blanks.

Blank loading only seen on 1969 production. The specimens below are movie blanks.

Blank loading used by the police for dog training excercises.

Blank loading used by the police for dog training excercises.

BOSS Ammunition was a company that loaded cartridges for the commercial market during the 1980’s. They used mainly PMP components. The blue primer annulus is indicative of BOSS.

OTHER AND EXPERIMENTAL LOADINGS ON PMP CASES.

Specimen looks like it was loaded with the 178 grain .380 Mk.2 Revolver bullet. The 178 grain was discontinued by PMP in 1969 and replaced by the 165 grain Gilding Metal bullet.

Specimen looks like it was loaded with the 178 grain .380 Mk.2 Revolver bullet. The 178 grain was discontinued by PMP in 1969 and replaced by the 165 grain Gilding Metal bullet.

Specimen is loaded with a lightweight brass bullet with deep cavity.

Specimen is loaded with a lightweight brass bullet with deep cavity.

Specimen above loaded with cone bullet, the same as what was used on the 9mm P loadings.

Specimen above loaded with cone bullet, the same as what was used on the 9mm P loadings.

Loaded with a hollow point nickel clad lead bullet by a company called Continental Arms.

Experimental COBRA loadings, still looking for information.

Experimental COBRA loadings, still looking for information.

The first specimen with 92 P was a Police contract load. The last specimen is also a COBRA load. It is speculated that these cases were manufactured by PMP for an unknown export contract. These cases were also found on ammunition from the Hansen Cartridge Co. and it might be that some of the overruns from the PMP order were sold to Hansen. The 6/92 is in all probability a date and not a lot number.

The cartridges below were loaded by Hirtenberg during the embargo years.

Eliminator load (NGA)

Eliminator load (NGA)

Might be a type of proof load

Might be a type of proof load

Chemically cleaned case. This is similiar to a 45 ACP loading from the mid 1980’s from a company called SW Products, although not confirmed.

Anti-Hijack loading with Teflon bullet. These were more extensively tested on the 9mm Parabellum.

Anti-Hijack loading with Teflon bullet. These were more extensively tested on the 9mm Parabellum.

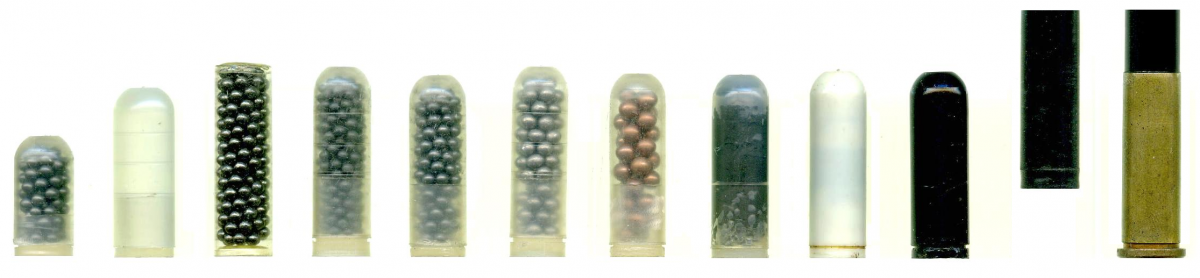

From RSACCA Newsletter #218 (Third Quarter 2006). In an attempt to develop a short-stop cartridge a number of plastic sabots filled with various size shot were used to gather data relating to velocity, energy transfer, penetration etc. (#2 shows an empty sabot). It was discovered that the empty space between the shot was wasted space. A Tungsten paste was developed, which worked very successfully. Sabots #8, 9 and 11 above are filled with this paste. #11 was the final sabot style. It is believed this was a project conducted at CSIR, (Council for Scientific and Industrial Research) Pretoria. I have however not been able to find any additional info on this project yet.

The AMT headstamp was by a company called AmmuTech from Wierda Park. a suburb in the city of Centurion which is situated halfway between Pretoria and Johannesburg. It was only known with a 1997 date. The middle specimen is a nickel-plated case. The last three specimens were part of some type of display board. They are dummy loads with NGA Cu clad bullets.

NGA

The third specimen is a show dummy from the 1998 DEXA (Defence Exposition Africa) show. Specimen with yellow base is a proof loading. The specimens with red and green bases are are tool blanks.

The specimens below were also loaded by NGA. Usually they used cases available at the time

The yellow tipped blank was called a Boulder Buster and used in a special barrel on construction sites.